What is a breather valve?

A breather valve is a device used to control the flow of gas within a tank, container, or system. Its primary function is to prevent overpressure and vacuum, reduce volatilization, and maintain pressure balance. It maintains system balance through an automatic adjustment mechanism, ensuring safety and stability.

The operating principle of a breather valve is based on the balance between gas pressure and spring reaction force. When the pressure within the container exceeds a preset value, the gas pressure pushes the valve disc open, allowing the gas to escape. When the pressure falls below the preset value, the spring reaction force closes the disc, preventing external gas from entering and maintaining a stable pressure within the container.

Breather valves play a vital role in industrial production and are widely used in the petroleum, chemical, pharmaceutical, and food industries. They maintain pressure balance in tanks, containers, and piping systems, preventing equipment damage or leaks caused by overpressure or vacuum. Breather valves not only protect the system from pressure anomalies but also reduce energy loss and resource waste, improving system efficiency and safety.

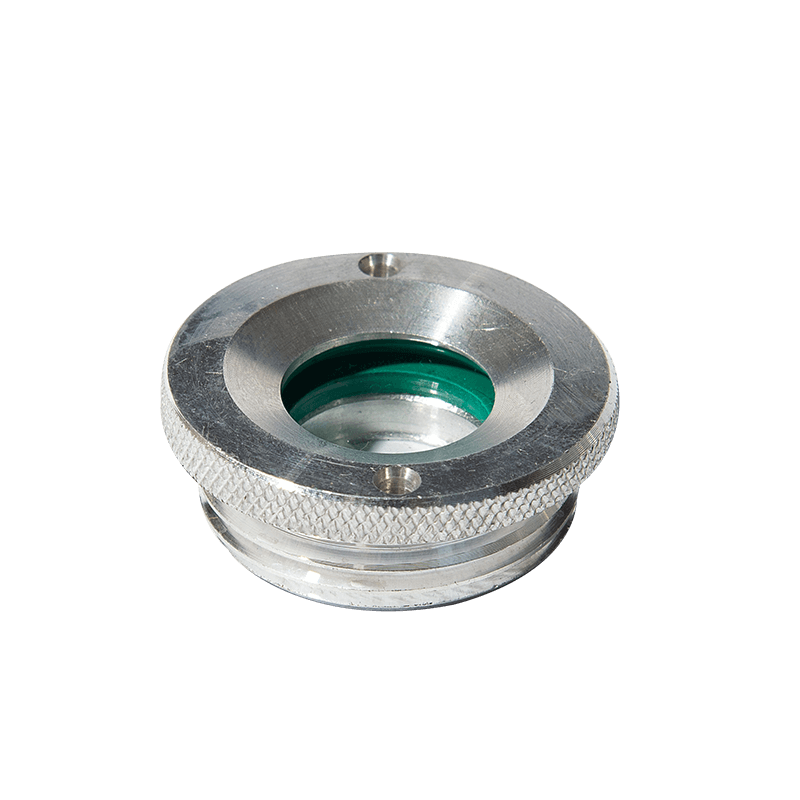

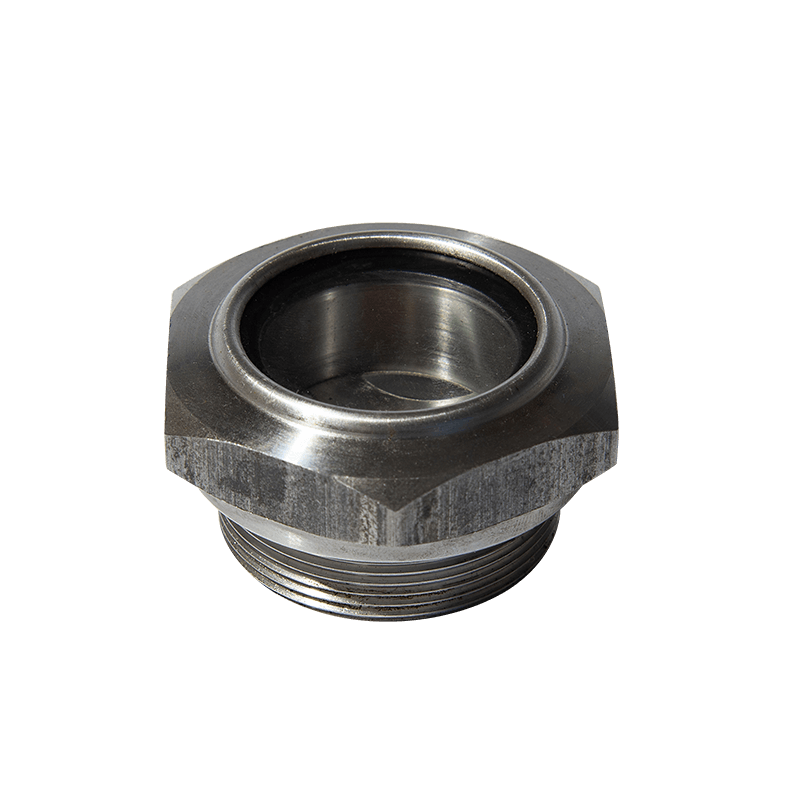

The structure of a breather valve typically includes components such as the valve body, valve seat, valve disc, valve stem, and spring. Materials such as cast steel, stainless steel, copper, and polytetrafluoroethylene are used to ensure strength, corrosion resistance, and sealing performance. Proper selection, installation, and maintenance of breather valves are crucial for ensuring safe operation and extending the life of the equipment.

How to Select a Breather Valve?

Selecting a breather valve is a complex process that involves multiple factors, requiring comprehensive consideration based on the specific application scenario, tank conditions, media characteristics, and operating environment.

1. Determine the Application Scenario and Operating Conditions

Tank Type and Structure: The breather valve should be selected to match the tank type, structure, and size. For example, the breather valve installation location and specifications may differ for vertical and horizontal tanks.

Media Characteristics: The media stored in the tank (such as flammable, explosive, corrosive, or high vapor pressure) will influence the material selection and sealing performance requirements for the breather valve.

Operating Conditions: These factors, including temperature, pressure fluctuations, and ambient temperature, can affect the performance and life of the breather valve.

2. Determine the performance parameters of the breather valve.

Opening and closing pressure: The opening and closing pressure of the breather valve should be determined based on the tank's design pressure and operating pressure. Generally, the opening pressure of the breather valve should be slightly lower than the tank's design pressure to ensure timely gas release when pressure increases.

Ventilation volume: Calculate the required ventilation volume based on the tank's evaporation loss, gas flow rate, and operating conditions to ensure the breather valve meets actual needs.

Sealing performance: Select a breather valve with excellent sealing performance to prevent gas leakage and outside air ingress.

3. Select the appropriate breather valve type and specifications.

Ventilation valve type: Select the appropriate breather valve type based on the application scenario, such as a one-way breather valve, a two-way breather valve, or a flame arrester breather valve.

Specifications and dimensions: Select the appropriate breather valve specifications and dimensions based on the tank's capacity, gas flow rate, and pressure requirements.

Material selection: Select corrosion-resistant, high-temperature-resistant, or fire- and explosion-resistant materials based on the media characteristics and environmental conditions.

4. Installation and maintenance

Installation location: The breather valve should be installed on the tank top or in a suitable location to ensure smooth gas flow and avoid blockage or leakage. Maintenance and Inspection: Regularly inspect and maintain the breather valve to ensure proper operation, including cleaning, lubrication, and leak checks.

5. Safety and Reliability

Safety: Select a breather valve that meets safety standards to ensure it effectively protects the tank and personnel during abnormal conditions.

Reliability: Select a breather valve with high reliability and durability to reduce failures and maintenance costs.

6. Cost-Effectiveness

Cost-Effectiveness: Select a breather valve with the best performance and safety standards to reduce overall costs.

Contact Us