What Types of Breather Valves Are There?

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) play a crucial role in protecting these critical devices from overpressure or vacuum damage. As an important pressure/vacuum relief device, understanding the main types of breather valves and their applicable scenarios is key to ensuring operational safety and extending equipment life.

Content

What is a Breather Valve? — Core Functions and Importance

The main function of a breather valve is to control the internal pressure of the storage tank within the design limits. When the inflow or outflow of materials causes the pressure or vacuum level to exceed limits, the breather valve automatically opens, releasing or drawing in gas to maintain balance within the tank.

- Overpressure Protection: Prevents tank rupture due to excessive pressure caused by temperature rise or rapid filling.

- Vacuum Protection: Prevents tank collapse due to a vacuum created by material removal or temperature drop.

Main Types of Breather Valves

Breather valves can be classified in various ways, but the most common classification is based on their working principle and structure.

1. Classification by Working Principle

This is the most fundamental classification method, directly determining the release mechanism of the breather valve.

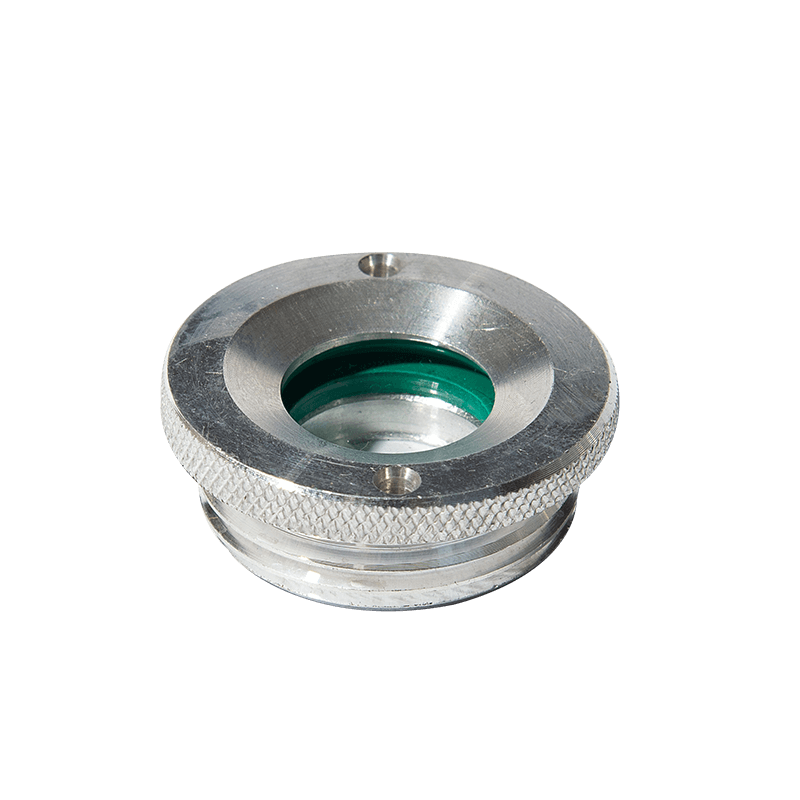

- Pressure/Vacuum Breather Valve (Conventional Type): This is the most common type, integrating both pressure and vacuum functions. It features a spring-loaded or counterweight-type opening mechanism; when a preset opening pressure or vacuum level is reached, the valve cover lifts to release pressure. The performance of this type of breather valve directly affects the safety and stability of the storage tank.

- Pressure-Only Breather Valve (Safety Valve): Used solely to prevent overpressure, commonly used in closed systems.

- Vacuum-Only Breather Valve (Vacuum Pressure Reducing Valve): Used solely to prevent vacuum, commonly used in transportation processes.

2. Classification by Structure and Application

- Pilot-Operated Breather Valve (or Pilot-Operated Safety Valve): Typically used in high-pressure applications or situations requiring more precise control. It has a pilot valve that controls the opening of the main valve, providing more sensitive and stable release characteristics.

- Breather valves with fire-retardant devices: On storage tanks containing flammable and explosive media, the vent of the breather valve must be equipped with a fire arrestor to prevent flames from entering the tank and causing an explosion.

- Cryogenic breather valves: Specifically designed for cryogenic storage tanks (such as LNG tanks), these require special sealing materials and structures to withstand extremely low operating temperatures.

Key Selection Criteria: Balancing Performance and Materials

When selecting a breather valve for a specific storage tank, in addition to considering the type of breather valve, its manufacturing materials and related technical parameters must also be considered.

- Material Selection: Considering the corrosiveness of the media, the structural components of the breather valve (such as the valve disc and seat) are typically made of stainless steel (such as 304, 316, etc., similar to the stainless steel used in your oil plugs, two-way ball valves, etc.) or corrosion-resistant alloys.

- Precision and Lifespan: High-quality breather valves should have high flatness, low opening pressure differential, and long service life. This is closely related to precision machining processes; for example, the glass in conference equipment also relies on high-precision CNC machining to ensure performance.

Proper selection and maintenance of breather valves are crucial for ensuring safe operation of storage tanks. Whether it's a conventional pressure/vacuum breather valve or a special breather valve with a fire-resistant device, precise matching based on actual operating conditions (such as media characteristics, working pressure, and ambient temperature) is essential.

Contact Us