What are the Symptoms of a Breather Valve Malfunction?

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can malfunction. Identifying early symptoms of breather valve malfunction is essential for ensuring tank safety, reducing product loss, and maintaining a safe production environment.

Content

I. Understanding the Working Principle of Breather Valves: Guardians of Safety and Efficiency

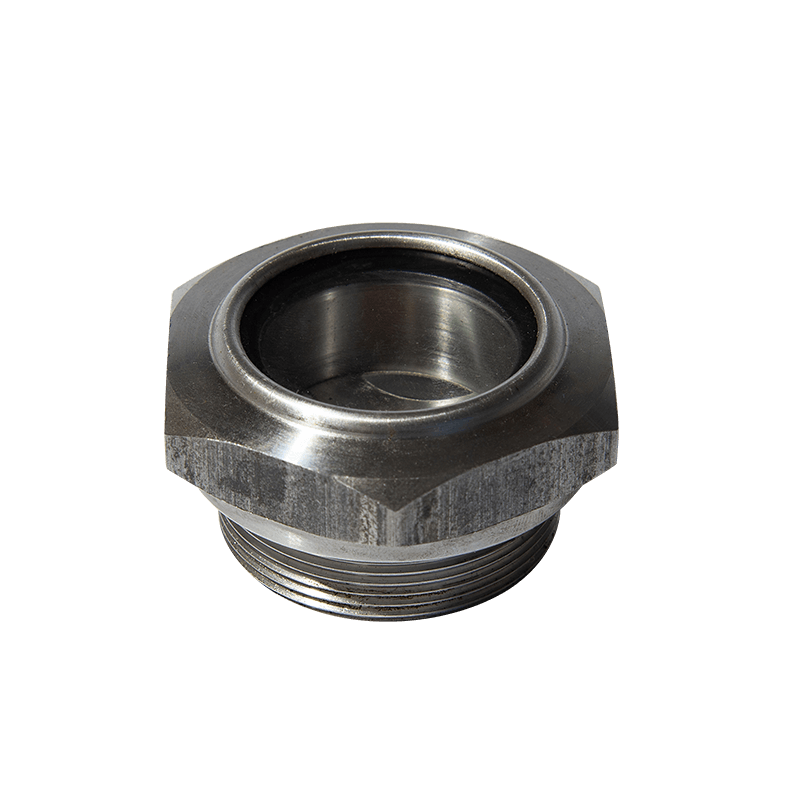

A breather valve (also commonly known as a pressure/vacuum safety valve or P/V valve) automatically opens to release pressure (or allow air in) when the internal pressure of the tank reaches a set value, based on preset pressure and vacuum points. Once the pressure returns to a safe range, the valve closes again. A properly functioning breather valve ensures that the pressure inside the tank remains within a safe range while minimizing evaporation losses of volatile media.

II. Common Symptoms of Breather Valve Malfunction

When a breather valve malfunctions, the following obvious symptoms may appear, requiring timely identification and handling by operators:

1. Obvious Leakage or Abnormal Noise (Abnormal Exhaust)

This is the most direct malfunction signal.

Symptoms: 1. Continuous hissing sound from the breather valve at non-design operating pressures, or observation of media leakage (such as steam or odor) at the valve port.

Fault Analysis: This could be due to damage to the valve seat or disc, aging/hardening of the seals, or foreign objects causing a leak, commonly known as "air leakage". This not only results in media loss but may also create safety hazards below the pressure relief point.

2. Tank Deformation (Abnormal Intake or Exhaust)

This is one of the most dangerous fault symptoms.

Symptoms: The tank wall exhibits inward concavity (collapse) or outward bulging (bulge).

Fault Analysis:

- Inward Concavity: A vacuum-side (intake function) fault, possibly due to the breather valve's vacuum disc being stuck, jammed, or blocked, preventing timely air replenishment when the tank pressure is lower than atmospheric pressure.

- Outward Bulging: A pressure-side (exhaust function) fault, possibly due to the breather valve's pressure disc being stuck, jammed, or blocked, preventing timely gas discharge when the tank pressure is excessively high.

3. Valve Fails to Reset or Operates Frequently

The breather valve should reset quickly and accurately after completing its depressurization or intake task.

Symptoms: The breather valve remains open after pressure recovery (fails to reset), or opens and closes excessively frequently with slight pressure fluctuations in the tank (frequent operation/flutter).

Analysis: This could be due to a bent guide rod, worn guide sleeve, inaccurate counterweight or spring settings, or crystallization or accumulation of the medium causing component adhesion.

4. Abnormal Pressure Gauge Readings

The breather valve's condition can be indirectly determined by measuring the internal pressure of the tank.

Symptoms: The tank pressure continuously rises, far exceeding the breather valve's set opening value; or the pressure drops rapidly to an excessively low level during material extraction.

Analysis: After confirming the pressure gauge itself is not faulty, high pressure usually indicates a stuck pressure-side valve disc; low pressure (vacuum) usually indicates a stuck vacuum-side valve disc or a blocked intake port.

III. Prevention and Maintenance: Ensuring Tank Safety

The key to avoiding breather valve failure lies in regular inspection and maintenance:

- Regular Cleaning: Especially for breather valves handling easily crystallizing or viscous media, regularly inspect and remove scale or dirt from the valve seat, valve disc, and guide mechanism.

- Inspect Seals: Regularly replace aged seals and gaskets to ensure their flexibility and sealing performance.

- Anti-freezing Measures: In low-temperature environments, ensure that there is no water accumulation or ice formation on the valve body and outlet to prevent components from freezing and causing valve jamming.

- Functional Testing: Regularly perform online or offline functional tests on the P/V valve to verify that its opening pressure, vacuum degree, and reset performance meet design requirements.

Proper maintenance can greatly extend the service life of the breather valve, ensure the reliability of the tank safety valve function, and thus guarantee the safe operation of the entire tank system.

Symptoms of breather valve failure include abnormal venting (leakage), tank deformation, inability to reset the valve, and abnormal pressure readings. Recognizing these symptoms and combining them with regular breather valve maintenance is the primary task in ensuring the safe management of storage tanks containing flammable, explosive, or toxic substances.

Contact Us