How to Correctly Read the Oil Level?

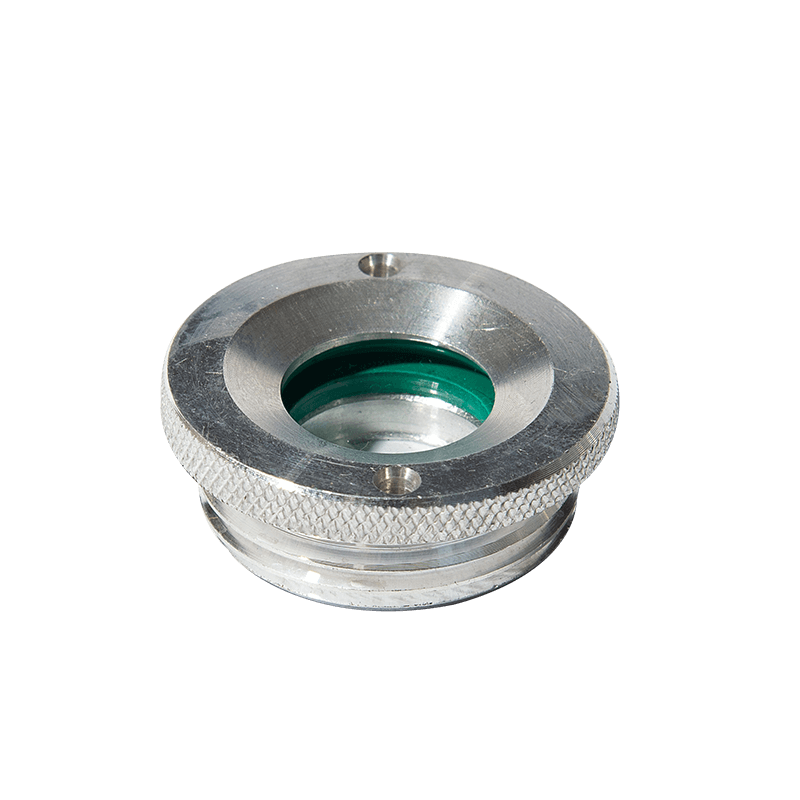

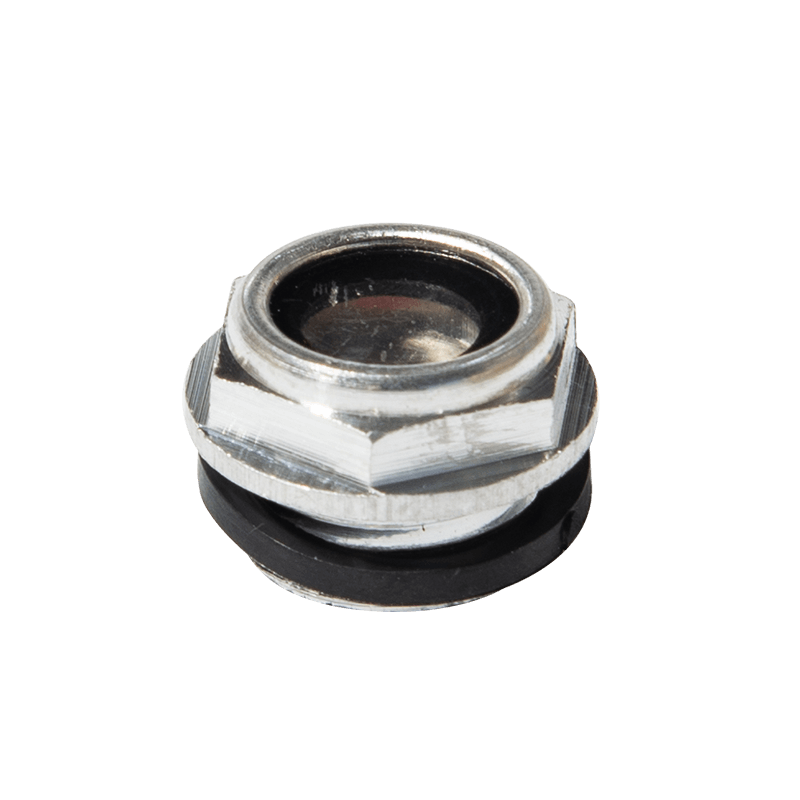

In industrial machinery and hydraulic systems, accurate oil level information is crucial. Excessively high or low oil levels can lead to equipment failure, decreased performance, and even shortened service life. The oil level sight glass provides a crucial window into your equipment's oil status.

As a common hydraulic accessory, the oil level sight glass is designed to provide operators with a clear, intuitive way to observe oil levels. Correctly reading the information on the oil level sight glass is the first step to ensuring safe and efficient equipment operation.

Content

I. Understanding the Oil Level Sight Glass and Its Function

Oil level sight glasses are typically mounted on the side or top of equipment requiring lubrication or hydraulic fluid, such as oil tanks, hydraulic stations, gearboxes, pumps, or cylinders.

Their primary functions are:

- Visual display: Through a transparent glass or plastic window, operators can easily see the oil level in the tank without opening the equipment.

- Oil level warning: The sight glass is typically marked with two lines or limits: an upper limit (Maximum/H) and a lower limit (Minimum/L).

- Normal oil level: The oil level should be between these two limits.

- Excessive oil: This may increase operating resistance or even lead to leakage.

- Insufficient oil: This may result in poor lubrication, idling, or overheating, leading to mechanical failure.

- Oil Condition Monitoring: Experienced operators can also use the sight glass to observe the oil's color, clarity, and the presence of bubbles or emulsification to initially determine whether the lubricating or hydraulic oil is contaminated or deteriorating.

II. Correctly Reading the Oil Level Sight Glass

To ensure accurate readings, please follow these steps:

Shut down and allow the machine to rest (critical)

Before reading the oil level, shut down the machine and wait for a period of time (usually several to ten minutes) to allow the circulating oil to drain back to the bottom of the reservoir. This is a critical step for ensuring accurate oil level readings in hydraulic machinery and pumps.

Tip: If the oil level is read immediately after the machine is shut down, the oil level may be incorrectly low, resulting in misreading.

Cleaning the Sight Glass Surface

Wipe the exterior of the oil level sight glass with a clean cloth to remove dust, oil, or moisture to ensure a clear view. A cloudy sight glass may result in erroneous readings.

Determining the Oil Level

Find the upper (upper limit) and lower (lower limit) markings on the sight glass.

The normal oil level should be between these two lines, indicating balanced oil.

Keep Your Eyes Level

When observing, keep your eyes level with the oil level in the sight glass to avoid errors in reading due to perspective deviations (such as looking sideways from above or below).

Determining the Oil Level

If the oil level is between the upper and lower limits, the oil level is normal.

If the oil level is below the lower limit, refill the hydraulic or lubricating oil immediately.

If the oil level is above the upper limit, drain the oil to avoid increased resistance or abnormal internal pressure.

III. Oil Level Glass Maintenance and Related Terms

As an observation window, the oil level glass itself requires important maintenance:

- Regular Inspection: Inspect the glass or plastic for cracks, aging, or severe discoloration, which may affect accurate viewing.

- Cleaning and Maintenance: If dirt adheres to the inside of the sight glass and cannot be removed through external cleaning, professional replacement or cleaning may be required to ensure accurate oil level monitoring.

- Related Accessories: When checking the oil level, also pay attention to the hydraulic joints, oil plugs, and the entire hydraulic system for signs of leaks to ensure the oil tank is properly sealed.

Proper use and maintenance of the oil sight glass is crucial to ensuring the long-term and stable operation of your mechanical equipment (whether it's a cylinder, diesel engine, or hydraulic station). Through simple and standardized operation, you can effectively extend the life of your equipment and reduce the risk of failure.

Contact Us