What is the working principle of an oil level sight glass?

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation device) is an important component in achieving this goal.

Content

I. Basic Structure of an Oil Level Sight Glass

To understand the working principle of an oil level sight glass, it is first necessary to understand its basic structure.

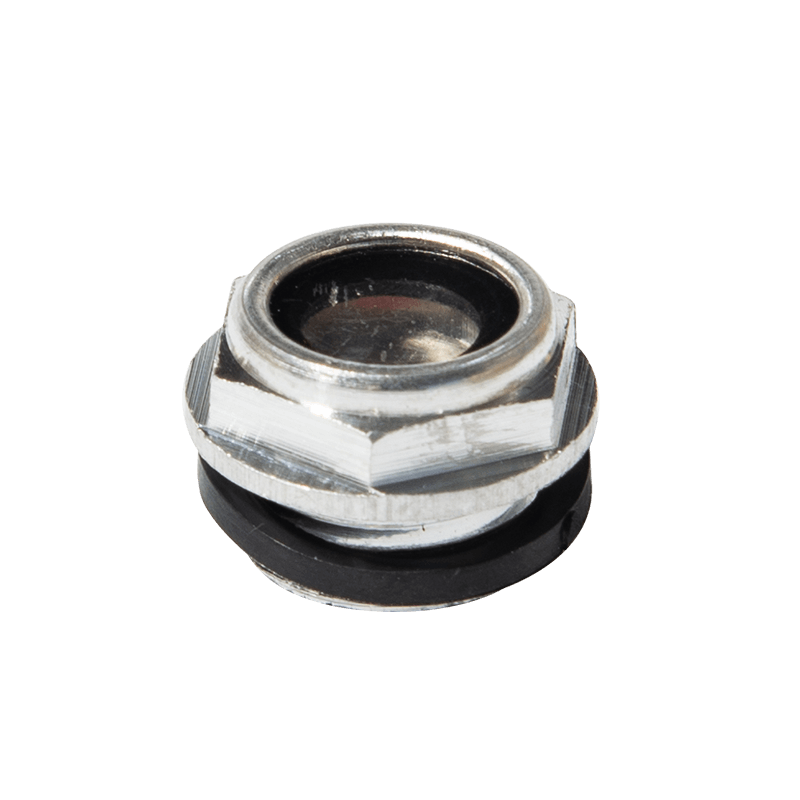

Based on the information you provided, an oil level sight glass is typically installed on the housing or oil tank of machinery that uses oil. Its core components include:

- Observation window (glass or transparent plastic): This is the light-transmitting part through which the user directly observes the oil, requiring high transparency and certain resistance to temperature, pressure, and oil corrosion.

- Body/Frame: Usually made of metal (such as aluminum, brass, or stainless steel) or high-strength plastic, used to fix and seal the observation window to the equipment wall.

- Sealing components (O-rings or gaskets): Ensure that the connection between the oil level sight glass and the equipment is leak-proof.

- Scale or markings (optional): Used to indicate the upper and lower limits of normal oil volume, i.e., the upper and lower oil level lines (boundaries).

II. Simple and Efficient Working Principle of Oil Level Sight Glasses

The working principle of oil level sight glasses is based on two fundamental physical concepts: the principle of communicating vessels and the principle of light refraction.

1. Principle of Communicating Vessels (Indirect Oil Level Sight Glasses)

For some elongated or tubular oil level gauges (generally defined as oil level sight glasses) installed on the side of the oil tank, they often utilize the principle of communicating vessels:

- Communication: The oil chamber of the sight glass is connected to the oil tank inside the equipment.

- Balance: According to the principle of communicating vessels, under hydrostatic equilibrium, the oil surface inside the tank and in the observation window of the oil level sight glass will remain at the same horizontal level.

- Indication: Therefore, by observing the oil level displayed in the sight glass, the user can directly know the current oil volume inside the equipment.

2. Principle of Light Refraction (Intuitive Observation Oil Level Sight Glass)

For the most common circular threaded oil level sight glass, the principle is more intuitive, mainly utilizing the refraction of light in different media and the color of the oil:

- Observation Window: When light passes through the sight glass, the angle of refraction differs depending on whether the interior is filled with oil (one medium) or air (another medium).

- Oil Level Boundary: The oil level sight glass clearly shows the interface between the oil (usually yellow or brown) and the air or vapor inside the tank, i.e., the oil level.

- Oil Level Judgment: Users only need to observe whether the oil surface is between the marked upper and lower lines (boundaries) to determine if the oil level is normal. If the oil level is above the upper limit, it indicates too much oil; if it is below the lower limit, it indicates too little oil. Both require timely adjustment or replenishment.

III. Importance and Application of Oil Level Sight Glasses

As an important monitoring device for hydraulic machinery and lubrication systems, the oil level sight glass's function is not merely aesthetic.

- Functional Assurance: Correct oil level is essential for the normal operation of hydraulic machinery such as cylinders, pumps, hydraulic valves, hydraulic power units, and diesel engines.

- Fault Prevention: Too much or too little oil will affect mechanical function, causing malfunctions or accidents and shortening service life. Oil level sight glasses help operators quickly identify and resolve these problems.

- Ease of Maintenance: It provides a simple, quick, and non-invasive method for checking oil levels, greatly simplifying routine equipment maintenance.

By understanding how oil level sight glasses work, users can better recognize the importance of regularly checking oil levels and ensuring that equipment is always in optimal working condition.

Contact Us