What are the main functions and usage of an oil level sight glass (oil gauge)?

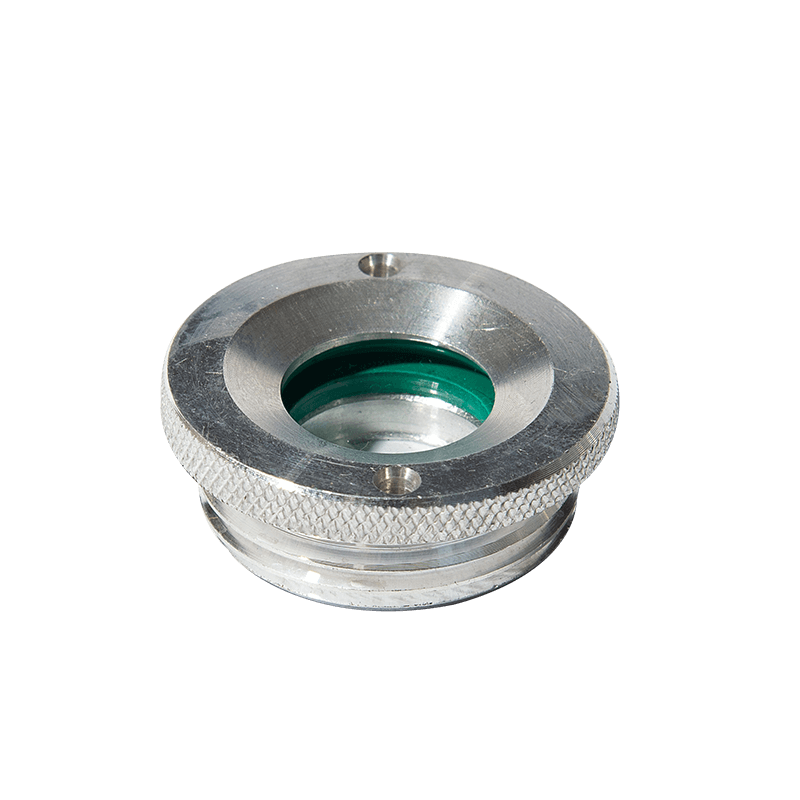

The primary function of an oil level sight glass (oil gauge) is to monitor and display the oil level in mechanical equipment or systems to ensure it is within the normal operating range. Through the transparent sight glass, operators can visually observe the oil level without disassembling the equipment, allowing them to promptly detect low or high oil levels and prevent equipment failure or damage caused by insufficient or excessive oil.

Using an oil level sight glass typically involves the following steps:

Installation and Location: An oil level sight glass is typically installed in the equipment's oil tank or oil system. Oil level changes are observed through a transparent glass or plastic tube (such as a cylindrical or circular sight glass).

Observation and Reading: The operator observes the oil level through the transparent portion of the sight glass. The sight glass is typically marked to indicate the normal oil level range.

Regular Inspection and Maintenance: To ensure the accuracy of the oil level sight glass, it should be regularly inspected and cleaned to maintain its transparency and proper function.

Oil level sight glasses are widely used in industry and machinery, particularly in applications requiring real-time monitoring of oil levels, such as pumps, engines, and hydraulic systems. They are crucial for ensuring proper operation and extending the lifespan of equipment.

What precautions should be taken when using oil level sight glasses?

The following points should be noted when using oil level sight glasses:

Choosing the appropriate material and model: Select the appropriate material and model of oil level sight glasses based on actual needs to ensure they are suitable for the specific operating environment and oil type.

Operating temperature and pressure range: Pay attention to the operating temperature and pressure range of the oil level sight glass and avoid exceeding their allowable limits to prevent equipment damage or failure.

Avoiding oil foaming: Oil foaming can affect observation results, so it should be avoided as much as possible during operation.

Regular cleaning and maintenance: Clean the oil level sight glass regularly to maintain its transparency and proper function to ensure accurate readings.

Checking the integrity of the oil level sight glass: When checking the oil level, ensure there are no cracks or pits in the sight glass to ensure accurate oil level readings.

Regular Inspection and Maintenance: Perform regular inspections of the equipment and record operating parameters to ensure proper operation and extend its service life.

Professional Operation: When adding or replacing lubricating oil, this should be performed by a professional to ensure safety and proper operation.

The above precautions will ensure the effectiveness and safety of the oil level sight glass in practical applications.

Contact Us