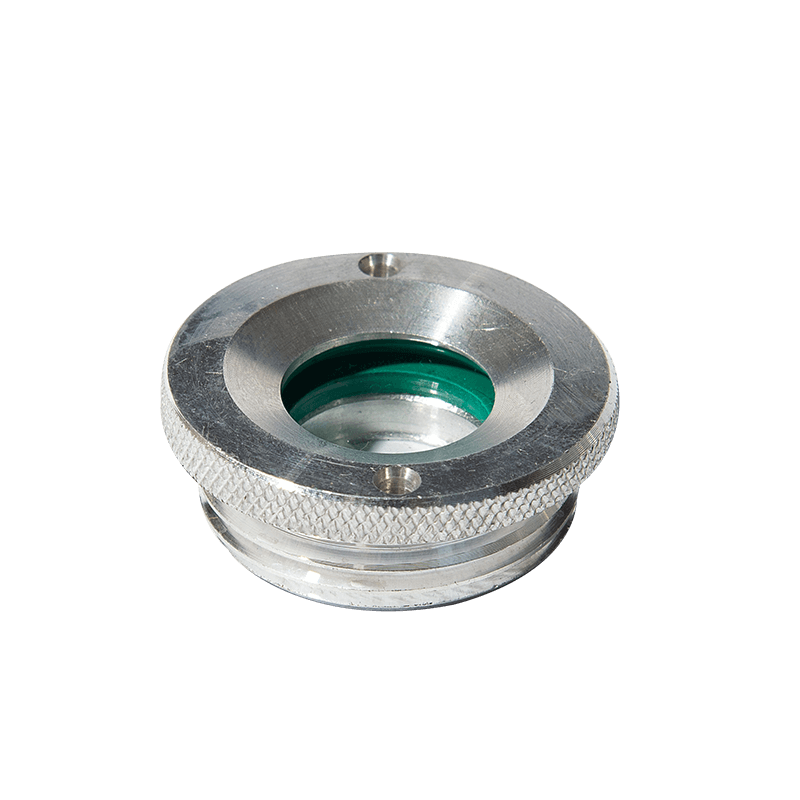

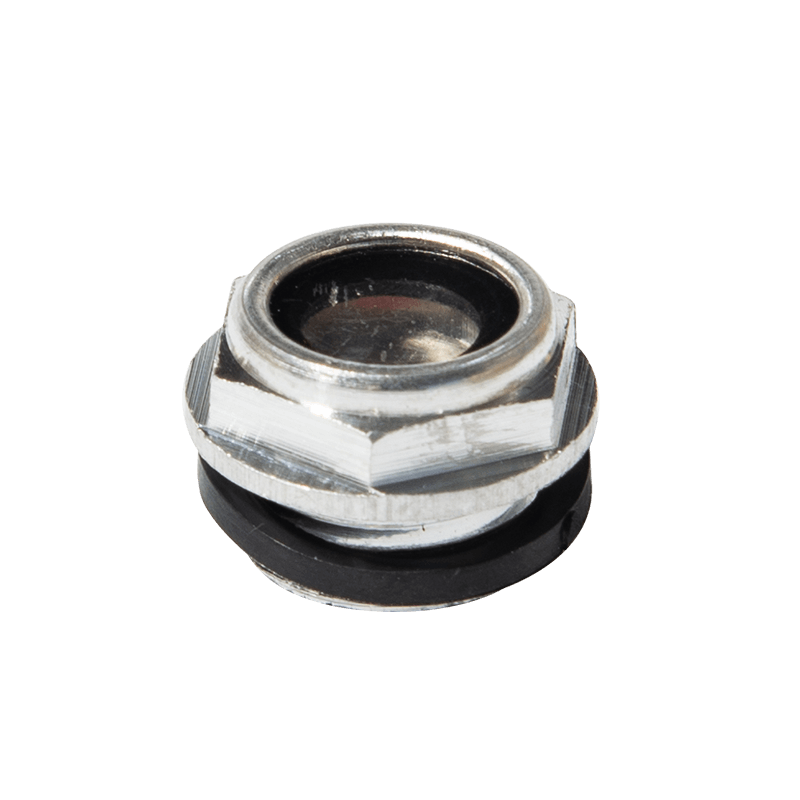

During the production process, how to ensure the surface treatment quality of the aluminum breathing filter valve shell to meet the requirements of rust prevention and wear resistance?

The aluminum breathing filter valve shell may be contaminated with oil during the processing process, and these oils will affect the effect of subsequent surface treatment. Generally, organic solvents or alkaline degreasers are used for cleaning. When using alkaline degreasers, immerse the shell in the configured degreasing liquid, and remove the oil on the surface of the shell through the chemical reaction and mechanical stirring of the degreasing agent and the oil.

Aluminum surfaces may form natural oxide scales or slight rust. Pickling is often used for treatment. Commonly used pickling solutions include sulfuric acid, nitric acid and other solutions. Immerse the shell in the pickling solution to remove oxide scales and rust products. After pickling, rinse with clean water immediately to prevent excessive corrosion. Alkaline etching can further remove impurities and slight defects on the surface of aluminum, making the surface more uniform. Put the shell into an alkaline etching solution containing sodium hydroxide, and it also needs to be fully washed with water after alkaline etching. After alkaline etching, there will be a layer of black corrosion products on the surface of the aluminum shell. The polishing process is to remove this layer of products and make the aluminum surface present a bright metallic luster. Generally, nitric acid solution is used for polishing.

This is the key process for the surface treatment of aluminum shells. The aluminum shell is used as an anode and placed in an electrolyte such as sulfuric acid. Through the action of direct current, a dense oxide film is formed on the surface of the shell. This oxide film has good rust and wear resistance. The oxide film after anodizing has a porous structure and is easy to adsorb impurities and corrosive media, so it needs to be sealed. Commonly used sealing methods include hot water sealing and normal temperature sealing. Hot water sealing is to immerse the shell in hot water so that the pores of the oxide film are filled with hydrated oxides; normal temperature sealing is to use a sealing agent containing nickel salts, cobalt salts, etc. for treatment.

The shell after surface treatment and sealing needs to be dried to remove residual moisture on the surface. Hot air drying or drying oven drying can be used. In order to further improve the anti-rust and wear resistance, the surface of the oxide film can be coated, such as spray paint, powder coating, etc. Before coating, ensure that the shell surface is clean and dry, and the thickness and uniformity of the coating should be controlled during the coating process.

Visually check whether the shell surface is flat and smooth, and whether there are scratches, bubbles, peeling and other defects. Carry out salt spray tests, wear tests, etc. to evaluate the anti-rust and wear resistance of the shell. For example, the salt spray test lasts for a certain period of time to observe whether there is rust on the surface of the shell; the wear test uses a wear tester to test according to the specified number of frictions and pressures to check the wear of the coating or oxide film.

Contact Us