Can the Breather Valve effectively prevent oil seal leakage?

The Breather Valve is a valve device used to close equipment, containers or boxes to balance the air pressure difference between the inside and outside of the container. It is usually used in oil seal systems, reducers, gearboxes and other equipment to avoid leakage, oil seal damage or equipment failure caused by unbalanced air pressure.

Main functions:

Balance internal and external air pressure: Inside a sealed container, such as a reducer or transmission, the internal pressure will change continuously due to temperature changes, expansion of lubricating oil or thermal expansion and contraction of air. The Breather Valve balances the air pressure inside and outside the container by exhausting or inhaling air to prevent damage to the closed part of the equipment (such as oil seals, joints, etc.) due to excessive pressure.

Exhaust and ventilation: When the equipment is running, the air in the box will expand due to temperature changes, and the Breather Valve can exhaust excess gas. Conversely, changes in external environmental air pressure can also inhale air through the Breather Valve, thereby maintaining the sealing and stability of the equipment.

Prevent oil seal failure: Due to high temperature, pressure fluctuations or long-term operation of the equipment, the oil seal may be over-pressurized. The breather valve balances the air pressure to prevent damage to the oil seal caused by excessive internal pressure, thereby preventing oil leakage.

Applicable scenarios:

Reducers and gearboxes: In reducers or gearboxes, the internal air pressure increases due to the expansion of the lubricating oil or changes in temperature. The use of a breather valve helps to slow down this pressure fluctuation and avoid failure and leakage of the sealing oil seal caused by excessive internal pressure.

Oil and gas storage tanks: Used in oil and gas storage tanks, when the gas expands due to temperature changes inside the tank, the breather valve can help release excess gas to prevent the tank from exploding or being damaged.

Mechanical equipment: In mechanical equipment such as motors, hydraulic systems, compressors, etc., the breather valve helps maintain the balance of air pressure inside and outside the equipment and protects internal parts from damage due to excessive air pressure.

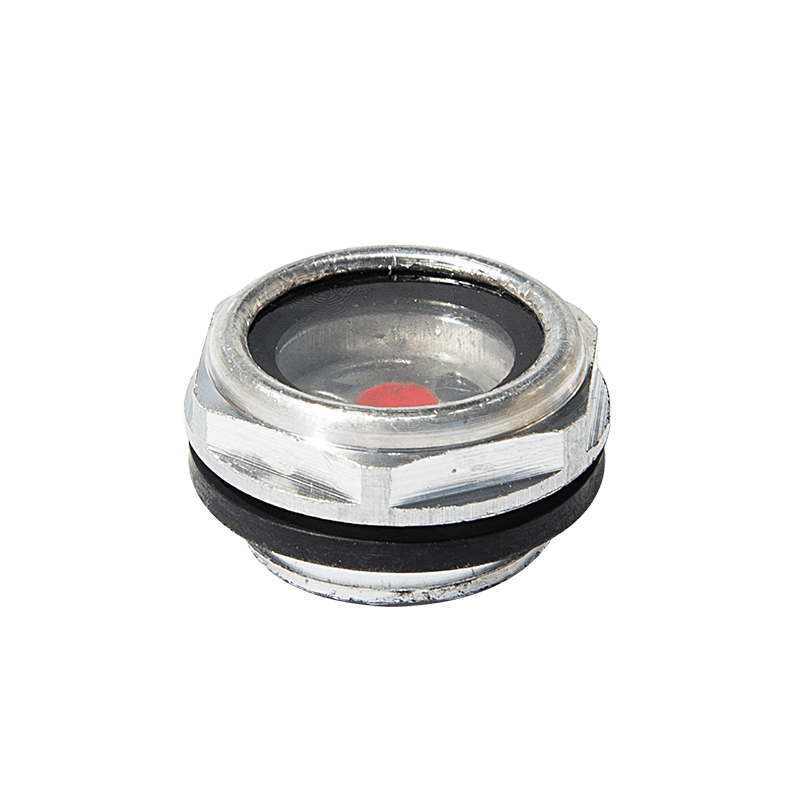

Structure and working principle:

The basic structure of the breather valve includes a valve body and a sealing mechanism. There is usually a spring or gravity-driven flap inside the valve body, which can automatically open or close according to changes in air pressure. When the internal air pressure exceeds the external pressure, the valve will open to discharge excess gas; when the external pressure increases or the temperature decreases, the valve will close to prevent air or gas from entering.

Common types of Breather Valves:

Automatic exhaust type: It can automatically adjust the ventilation volume according to the change of air pressure.

Manual adjustment type: It needs manual adjustment, and the opening and closing state of the Breather Valve is controlled by rotation or switch.

Breather Valve can effectively prevent oil seal leakage

1. Balance internal and external air pressure

Inside the reducer or closed equipment, lubricating oil and air will expand at high temperature, causing the internal air pressure to increase. If the box does not have a suitable ventilation system, when the internal pressure is too high, the oil seal will be subjected to excessive external pressure, causing it to fail or age. At this time, the sealing of the oil seal is reduced, and oil leakage may eventually occur.

The function of the Breather Valve is to balance the air pressure inside and outside the box through its breathability. When the gas inside the box expands due to temperature changes, the Breather Valve will discharge excess gas to avoid excessive pressure inside the box, thereby reducing the pressure on the oil seal and ensuring that the oil seal is not crushed.

2. Prevent oil seal failure

One of the common reasons for oil seal failure is the imbalance of air pressure inside and outside the box. Under high temperature or long-term operation, the air pressure inside the box will increase, while the external air pressure is relatively low. If there is no effective gas exhaust device, the air pressure difference will exert excessive pressure on the oil seal, causing the oil seal to deform, age or even fail, and then cause oil leakage.

After installing the Breather Valve, with the automatic adjustment of the air pressure difference, the internal and external air pressures remain balanced, thereby reducing the direct pressure on the oil seal, extending the service life of the oil seal, and effectively preventing the oil seal from failing due to excessive external force.

3. Prevent lubricating oil leakage

The Breather Valve can effectively discharge oil and gas evaporation caused by temperature increase, avoiding the failure of the oil seal due to excessive external force. If there is no exhaust function of the Breather Valve, the lubricating oil in the reducer may forcefully squeeze the oil seal after heat expansion, causing lubricating oil leakage, thereby affecting the normal operation of the reducer, and may even cause dry grinding damage to mechanical parts.

The Breather Valve can maintain the normal air pressure of the reducer in a high temperature environment, avoid excessive lubricating oil leakage and oil seal damage, and ensure the stability of the equipment during long-term operation.

4. Prevent other problems caused by high temperature

Since the lubricating oil and air in the reducer will expand at high temperatures, the high temperature may reach about 80°C. If there is no Breather Valve, the gas and oil pressure in the box will increase, which may cause the lubricating oil to accumulate at the oil seal, causing the oil seal to leak or damage. The exhaust function of the Breather Valve can release excess gas, reduce the pressure on the oil seal, and avoid oil leakage and equipment failure caused by high temperature.

5. Improve the operating environment of the reducer

In addition to oil seal protection, the Breather Valve can also maintain good ventilation inside the reducer and help effectively dissipate the temperature. By adjusting the airflow in the box, the influence of harmful substances such as moisture and accumulated air is reduced, further ensuring the stable operation of the equipment and reducing the aging and damage of the oil seal caused by environmental factors.

Contact Us