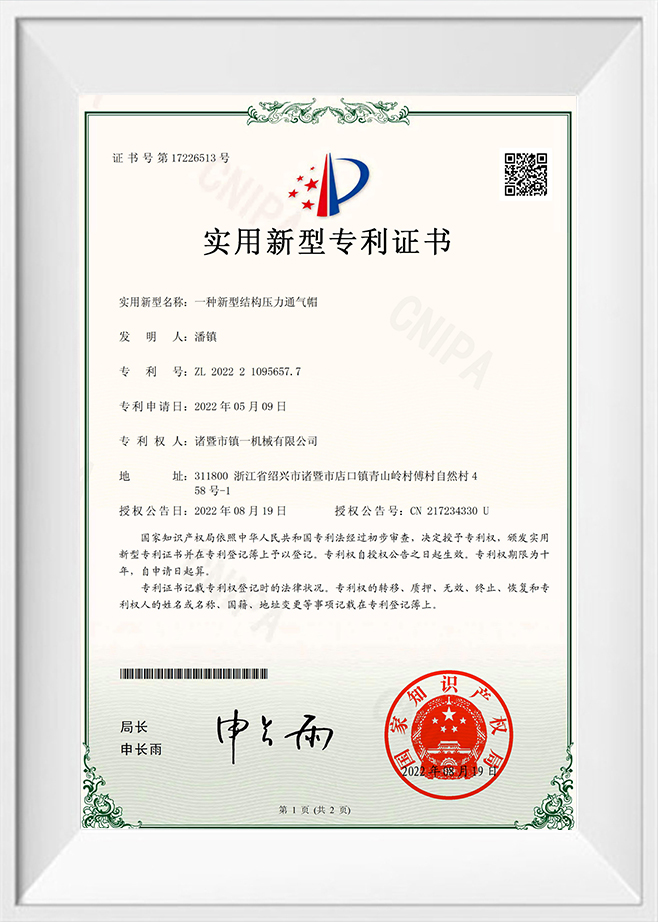

In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREFKM Sealing Element Supplier

information to be updated

information to be updated

-

-

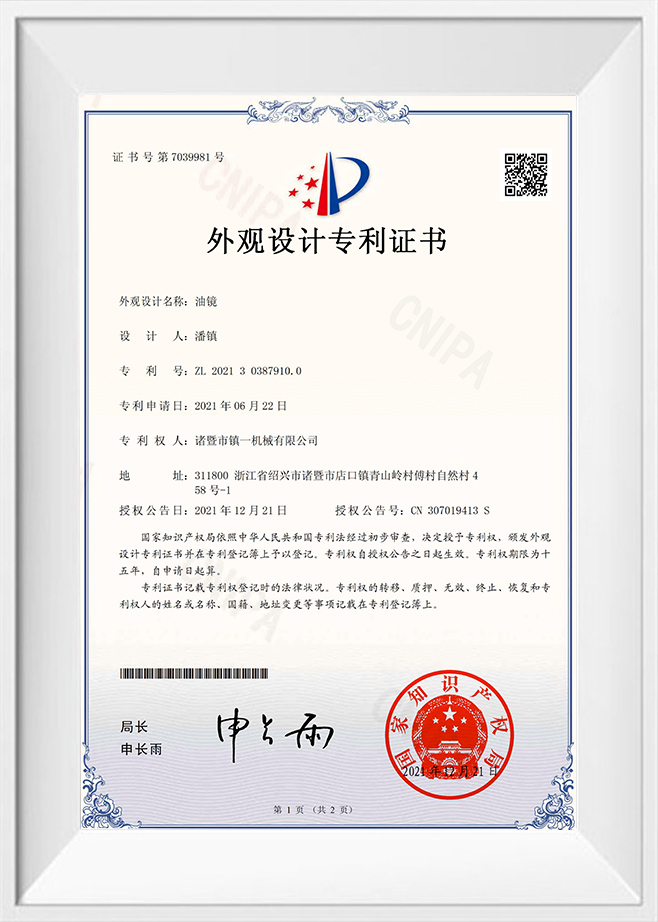

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

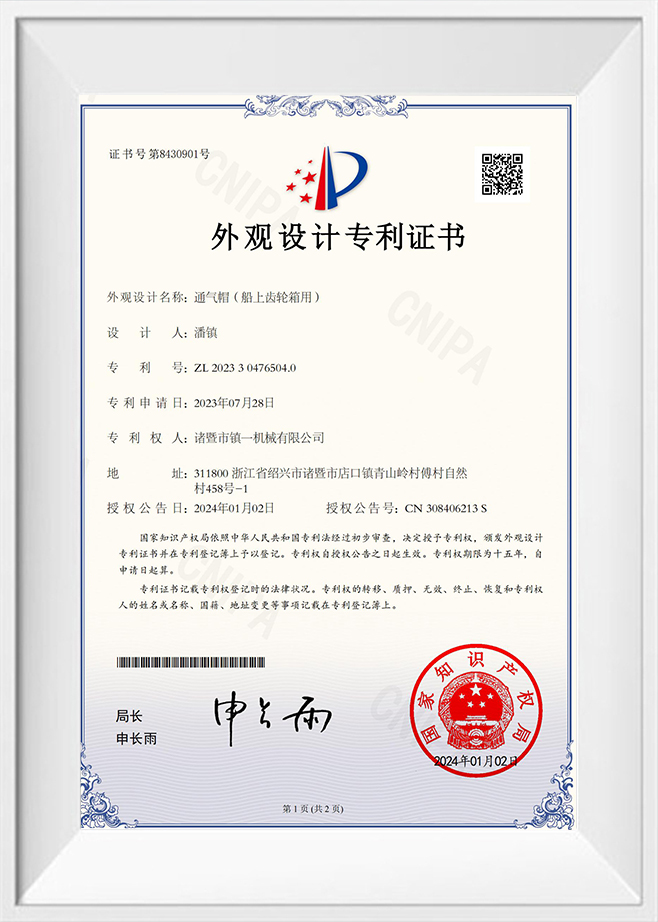

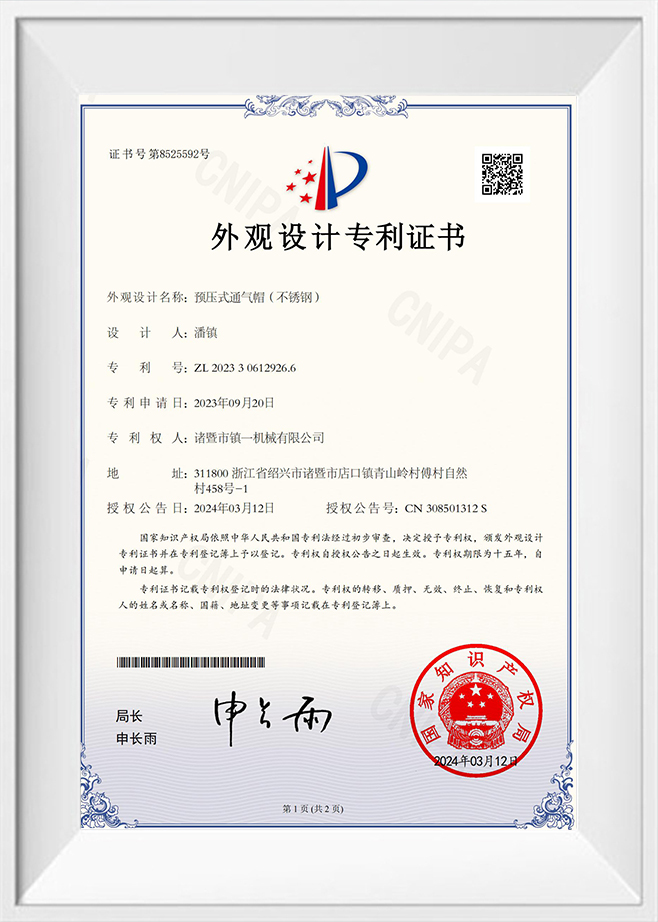

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

FKM Sealing Element exhibit excellent sealing performance within the working pressure and a certain temperature range. Its unique material properties and structural design enable the seal ring to maintain a good sealing effect under different pressure conditions. More importantly, as the pressure increases, the FKM seal can automatically adjust its sealing state, further enhancing the sealing performance and ensuring the stability and safety of the system operation.

On the contact surface between the seal ring and the moving parts, the FKM seal exhibits extremely low friction and a stable friction coefficient. This feature not only helps to reduce the energy consumption and wear of the equipment, but also ensures the smooth operation of the system. Even under long-term or high-load conditions, the friction coefficient of the FKM seal can remain stable, extending the service life of the equipment.

FKM Sealing Element have extremely strong corrosion resistance and can resist the erosion of a variety of chemical substances, including corrosive substances such as acids, alkalis, and salts. At the same time, its aging resistance is also excellent, and it can maintain stable performance for a long time in harsh environments such as high temperature, low temperature, and humidity. This means that FKM Sealing Element can maintain their original sealing effect and mechanical properties under various complex working conditions, extending the service life of the equipment.

FKM Sealing Element also have excellent wear resistance and can maintain a low wear rate during friction with moving parts. Even if a certain degree of wear occurs, FKM Sealing Element can automatically compensate through their unique structural design to maintain a stable sealing effect. This feature gives FKM Sealing Element a significant advantage in applications that require long-term operation and high reliability.

FKM Sealing Element have become an indispensable sealing element in various industrial equipment and systems with their excellent sealing performance, low friction and stable friction coefficient, excellent corrosion and aging resistance, excellent wear resistance and automatic compensation capabilities. Whether in automotive manufacturing, petrochemicals, aerospace or other fields, FKM Sealing Element have won wide recognition and trust with their outstanding performance.

.jpg)