In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREBrass Safety Valve Supplier

information to be updated

information to be updated

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

The brass safety valve is a safety device made of high-quality brass material. It is mainly used in various fluid systems to ensure that the system can automatically open and release pressure when the pressure rises abnormally, thereby protecting the system from damage. The choice of brass material not only gives the safety valve good corrosion resistance and strength, but also makes it have a certain aesthetics, suitable for a variety of industrial and civil environments.

The working principle of the brass safety valve is based on the balance between spring loading and medium pressure. When the system pressure exceeds the preset safety value, the spring is compressed and the valve disc opens, allowing the medium to flow out to reduce the system pressure. When the system pressure returns to the normal range, the elastic force of the spring causes the valve disc to close again, thereby preventing the medium from continuing to flow out. This automatic and fast response feature ensures the safety of the system when facing the threat of overpressure.

The brass material of the brass safety valve has good corrosion resistance and can be used for a long time in a variety of media environments without rusting or deterioration. Different pressure setting values can be customized according to customer needs to ensure the safe operation of the system under different working conditions. Brass safety valves usually use standard connection methods, which are convenient for quick connection with the pipeline system. At the same time, its compact structure and reasonable design make maintenance easier.

After strict quality control and testing, the brass safety valve can maintain stable performance during long-term use, ensuring the continuous and safe operation of the system. Brass materials not only have excellent mechanical properties, but also have certain decorative properties, so that the safety valve can not only meet safety requirements, but also improve the overall aesthetics of the system.

Brass safety valves are widely used in fluid systems in industries such as petroleum, chemical, electric power, metallurgy, food, and medicine, especially in situations where pressure needs to be controlled, such as boilers, pressure vessels, piping systems, heat exchangers, etc. Its reliable performance, good corrosion resistance and beautiful appearance make brass safety valves an indispensable safety device in these fields.

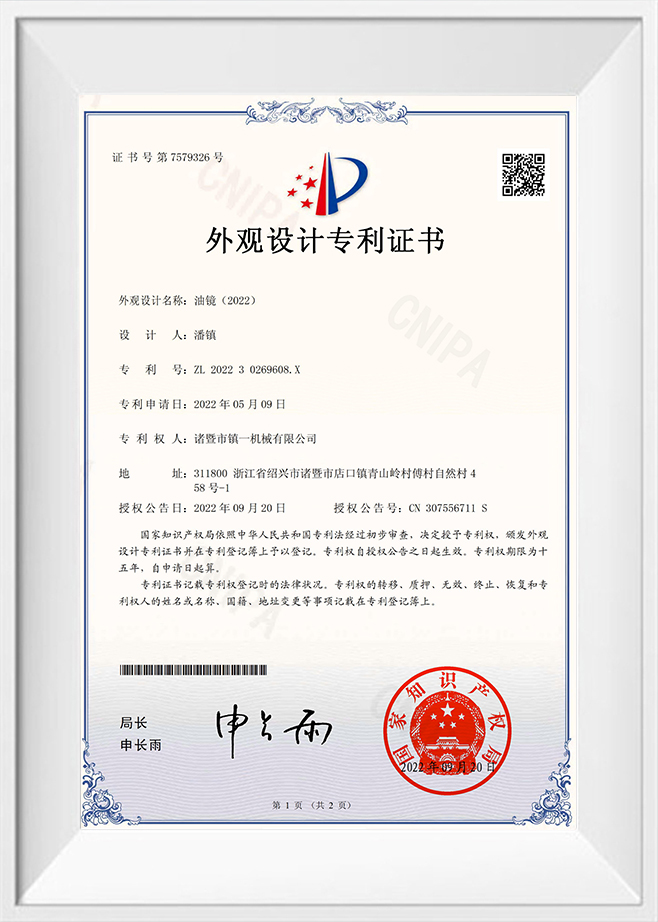

Our company was established in 2004 and has been focusing on reducers, air compressors and other industries for more than 20 years. As a comprehensive enterprise integrating R&D, production and sales, we are committed to providing customers with high-quality products and professional services. The company has an experienced technical team, including 5 professional technicians and nearly 30 operators of various types. With their superb skills and unremitting efforts, they ensure the excellent performance and reliability of their products.

.jpg)