In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREOil Level Sight Glass Manufacturer

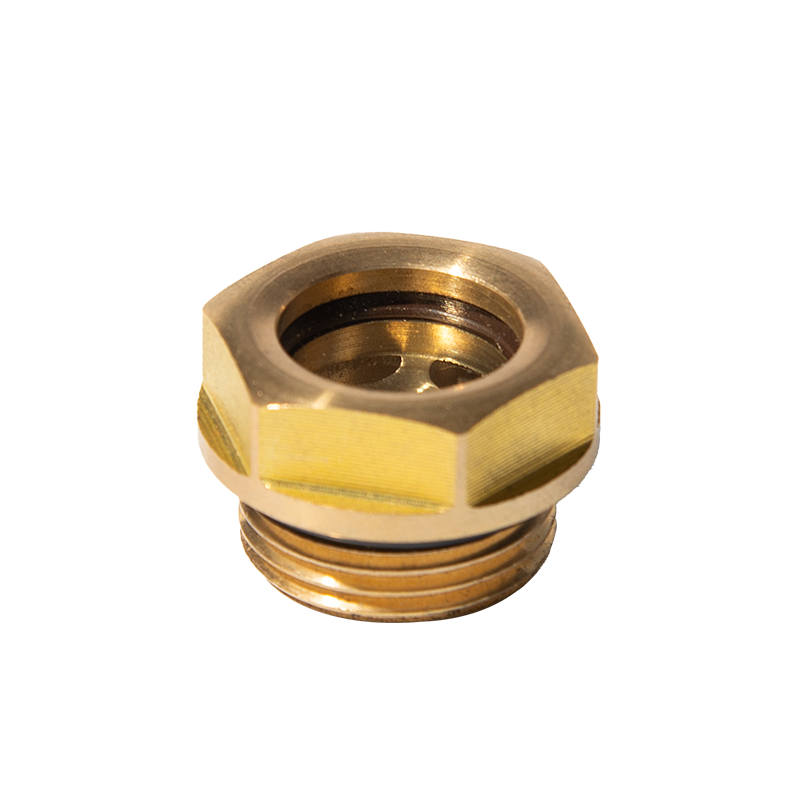

The oil gauge is a device used on oil-using machinery to observe the existing oil volume. The normal oil volume should be between the upper and lower lines (limits) marked. If it reaches above the upper line, it means that the oil volume is too large and should be adjusted. For example, Below the line, the oil should be replenished in time. Otherwise, not only will the machine's functions not be able to function normally, but mechanical failure or even accidents will occur, and the service life of the machine will be shortened.

-

Copper oil label

Material: Brass 58-3 Observe the mirror material: glass. (Optional tempered glass, high borosilicate glass) Sealing ring type: fluorine rubber FKM70°,...

Copper oil label

Product Description:

Material: Brass 58-3

Observe the mirror material: glass. (Optional tempered glass, high borosilicate glass)

Sealing ring type: fluorine rubber FKM70°, with brown as the main color. (Custom optional, NBR, silica gel, PC, EPDM).

Sealing ring at thread: NBR。 (Customized optional fluorine glue, silicone, PC, EPDM)

Recommended operating temperature: -

Recommended working pressure: lower

|

Brass oil mark metric thread |

|||||||

|

Ltem NO. |

Size |

A(mm) |

L(mm) |

L1(mm) |

L2(mm) |

D(mm) |

ZZ(mm) |

|

ZYZZ-TTM10 |

M10 |

M10*1 |

15 |

7 |

1.7 |

14 |

16 |

|

ZYZZ-TTM12 |

M12 |

M12*1.5 |

15 |

7 |

2 |

14 |

17 |

|

ZYZZ-TTM14 |

M14 |

M14*1.5 |

15 |

7.5 |

2 |

17 |

19 |

|

ZYZZ-TTM16 |

M16 |

M16*1.5 |

16.5 |

8 |

2 |

19 |

22 |

|

ZYZZ-TTM18 |

M18 |

M18*1.5 |

16.5 |

8 |

2 |

19 |

22 |

|

ZYZZ-TTM20 |

M20 |

M20*1.5 |

16.5 |

8 |

2 |

22 |

25 |

|

ZYZZ-TTM22 |

M22 |

M22*1.5 |

16.5 |

8 |

2 |

24 |

27 |

|

ZYZZ-TTM24 |

M24 |

M24*1.5 |

16.5 |

8 |

2 |

24 |

29 |

|

ZYZZ-TTM26 |

M26 |

M26*1.5 |

17.5 |

8.5 |

3 |

27 |

32 |

|

ZYZZ-TTM27 |

M27 |

M27*1.5 |

16 |

8 |

2 |

27 |

32 |

|

ZYZZ-TTM30 |

M30 |

M30*1.5 |

16.5 |

8 |

2 |

30 |

35 |

|

ZYZZ-TTM33 |

M33 |

M33*1.5 |

17.5 |

9 |

2.2 |

32 |

38 |

|

ZYZZ-TTM36 |

M36 |

M36*1.5 |

17.5 |

9 |

2.2 |

36 |

42 |

|

ZYZZ-TTM42 |

M42 |

M42*1.5 |

17.5 |

9 |

2 |

42 |

48 |

|

ZYZZ-TTM48 |

M48 |

M48*1.5 |

20 |

10 |

2.5 |

48 |

55 |

|

ZYZZ-TTM60 |

M60 |

M60*2 |

28 |

14 |

3.5 |

64 |

71 |

|

Brass oil standard thread inch and non-standard thread |

|||||||

|

ZYZZ-TTF12 |

M12 |

M12*1.25 |

15 |

7 |

2 |

14 |

17 |

|

ZYZZ-TTF27 |

M27 |

M27*2 |

16 |

8 |

2 |

27 |

32 |

|

ZYZZ-TTF30 |

M30 |

M30*2 |

16.5 |

8 |

2 |

30 |

35 |

|

ZYZZ-TTF33 |

M33 |

M33*2 |

17.5 |

9 |

2.2 |

32 |

38 |

|

ZYZZ-TTF36 |

M36 |

M36*2 |

17.5 |

9 |

2.2 |

36 |

42 |

|

ZYZZ-TTF42 |

M42 |

M42*2 |

17.5 |

9 |

2 |

42 |

48 |

|

ZYZZ-TTF48 |

M48 |

M48*2 |

20 |

10 |

2.5 |

48 |

55 |

|

ZYZZ-TTG14 |

1/4’ |

G1/4 |

15 |

7.5 |

2 |

17 |

19 |

|

ZYZZ-TTG38 |

3/8’ |

G3/8 |

16.5 |

8 |

2 |

19 |

22 |

|

ZYZZ-TTG12 |

1/2’ |

G1/2 |

16.5 |

8 |

2 |

22 |

25 |

|

ZYZZ-TTG34 |

3/4’ |

G3/4 |

17.5 |

8.5 |

3 |

27 |

32 |

|

ZYZZ-TTG1 |

1’ |

G1 |

17.5 |

9 |

2.2 |

32 |

38 |

|

ZYZZ-TTG114 |

1-1/4’ |

G1-1/4 |

17.5 |

9 |

2 |

42 |

48 |

|

ZYZZ-TTG112 |

1-1/2’ |

G1-1/2 |

20 |

10 |

2.5 |

48 |

55 |

|

ZYZZ-TTG2 |

2’ |

G2 |

28 |

14 |

3.5 |

64 |

71 |

|

ZYZZ-TTG212 |

2-1/2’ |

G2-1/2 |

27 |

15 |

3.5 |

79 |

89 |

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

Our company was founded in 2004 and has been focusing on the reducer, air compressor and other industries for more than 20 years. As a comprehensive enterprise integrating R&D, production and sales, we are committed to providing customers with high-quality and reliable pump accessories, reducer accessories, air compressor accessories and hydraulic oil tank accessories.

The oil level sight glass is a core product of our company. It is specially designed for oil machinery to observe the existing amount of oil inside the machinery. Through the oil level sight glass, users can intuitively understand the amount of oil in the oil machinery, thereby ensuring the normal operation of the machinery and extending its service life.

The main function of the oil level sight glass is to provide a clear field of view so that users can observe the liquid level of the oil inside the machinery. The oil level sight glass is usually marked with upper and lower lines (limits), which are used to indicate the normal range of oil volume. The normal oil volume should be kept between the marked upper and lower lines. When the oil volume exceeds the upper line, it means that the oil volume is too much, and the oil level sight glass will remind the user to adjust the oil volume to avoid abnormal operation of the machinery. On the contrary, when the oil level is lower than the lower line, the oil level sight glass will prompt the user to replenish the oil in time to prevent mechanical failure or accidents.

The oil level sight glass provides an intuitive way to observe the oil level, and you can understand the oil level without using complex instruments or performing tedious operations. By observing the oil level in time and adjusting it to the normal range, the oil level sight glass helps prevent mechanical failures and accidents caused by insufficient or excessive oil, thereby improving the safety of mechanical operation. Keeping the oil level within the normal range can extend the service life of the machinery and reduce maintenance and replacement costs, thereby bringing economic benefits to users.

Users should check the oil level sight glass regularly to ensure that it is clean, undamaged and able to work properly. When observing the oil level, users should follow the guidance of the product manual and operate the oil level sight glass correctly to avoid misreading or damaging the equipment. When the oil level sight glass is found to be faulty or damaged, users should contact professionals in time for repair or replacement to ensure the normal operation of the machinery.

In addition to the oil level sight glass, our company's product range also includes aluminum alloy oil gauges, oil sight glasses, breather caps, exhaust caps, air filters, pressure breather caps, oil cups, positioning oil cups, L-type oil cups and other pump accessories, reducer accessories, air compressor accessories and hydraulic oil tank accessories. These products have undergone strict quality control and performance testing to ensure their stable performance, safety and reliability.

.jpg)