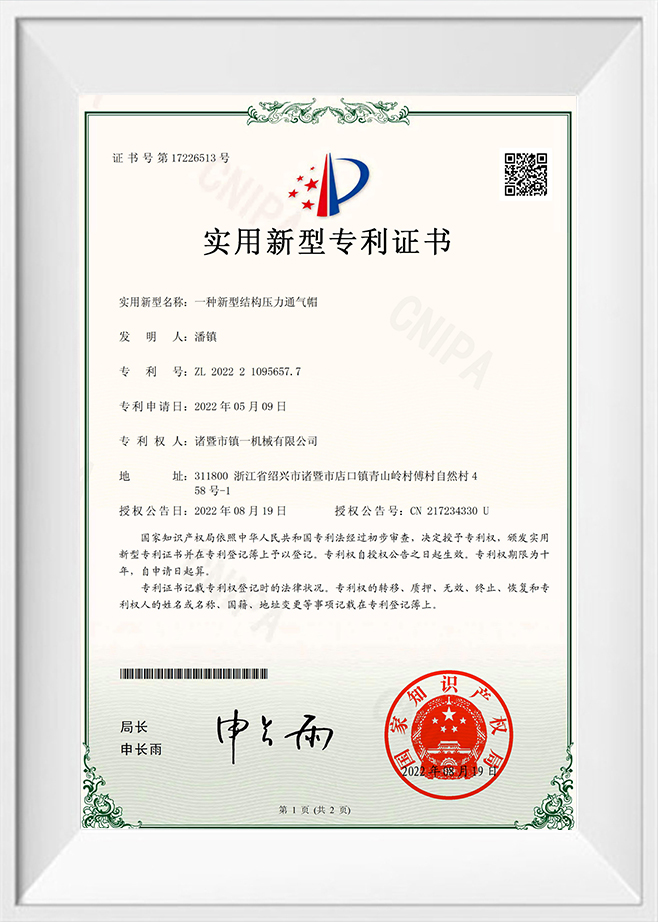

In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

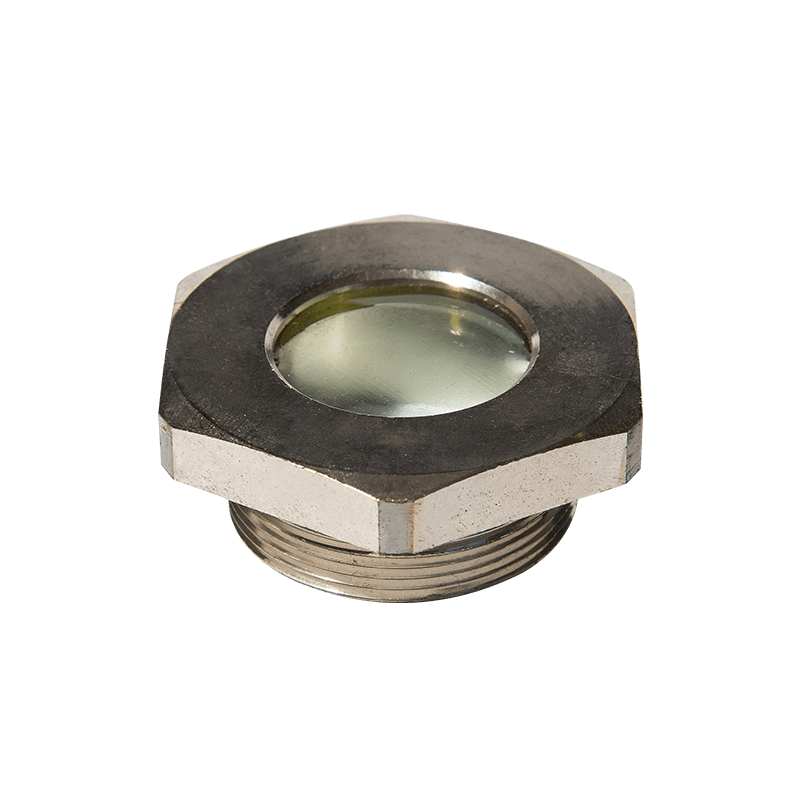

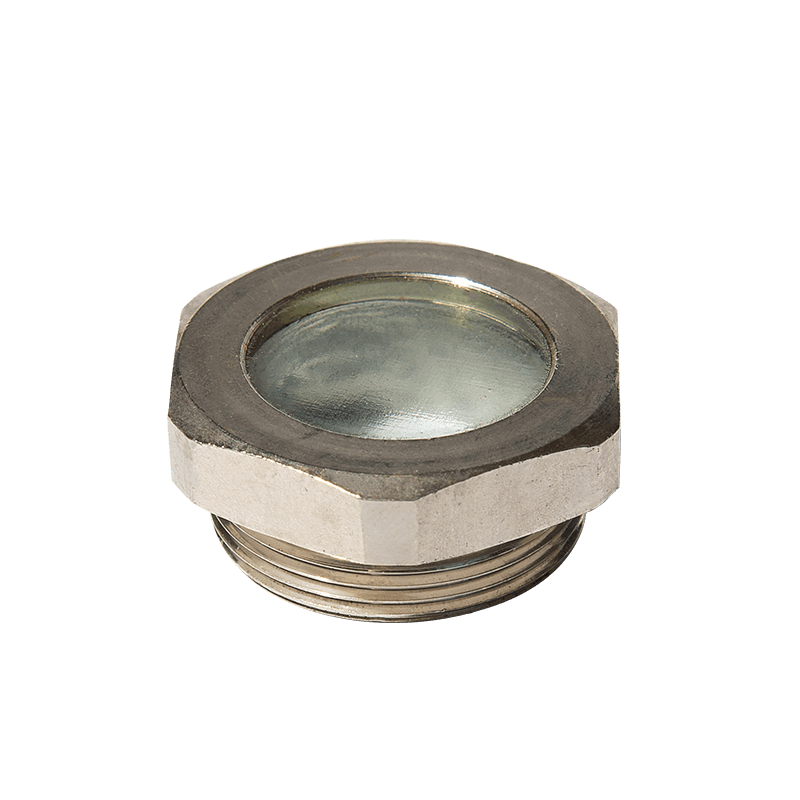

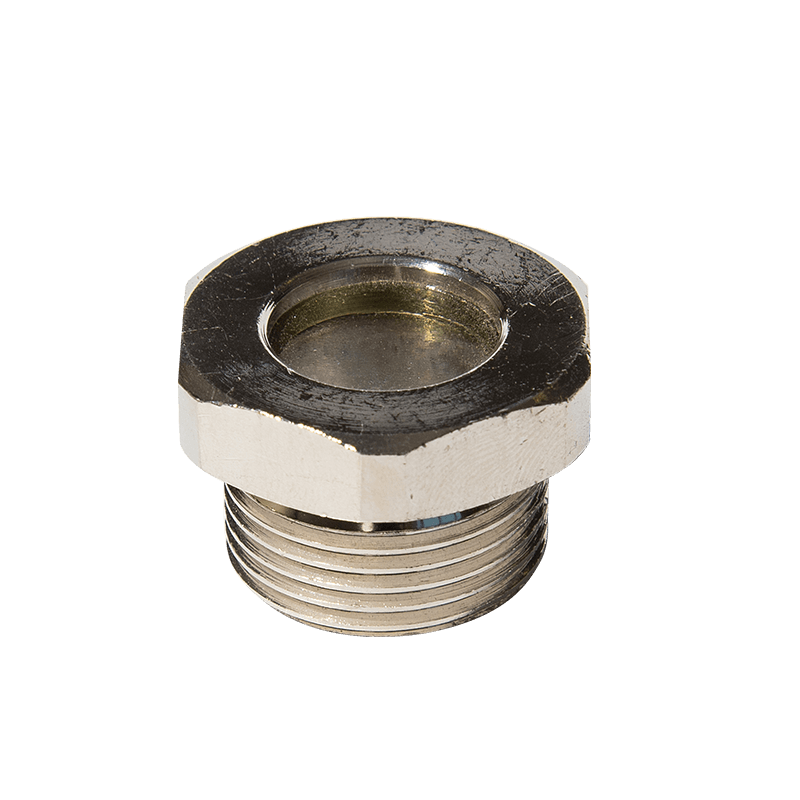

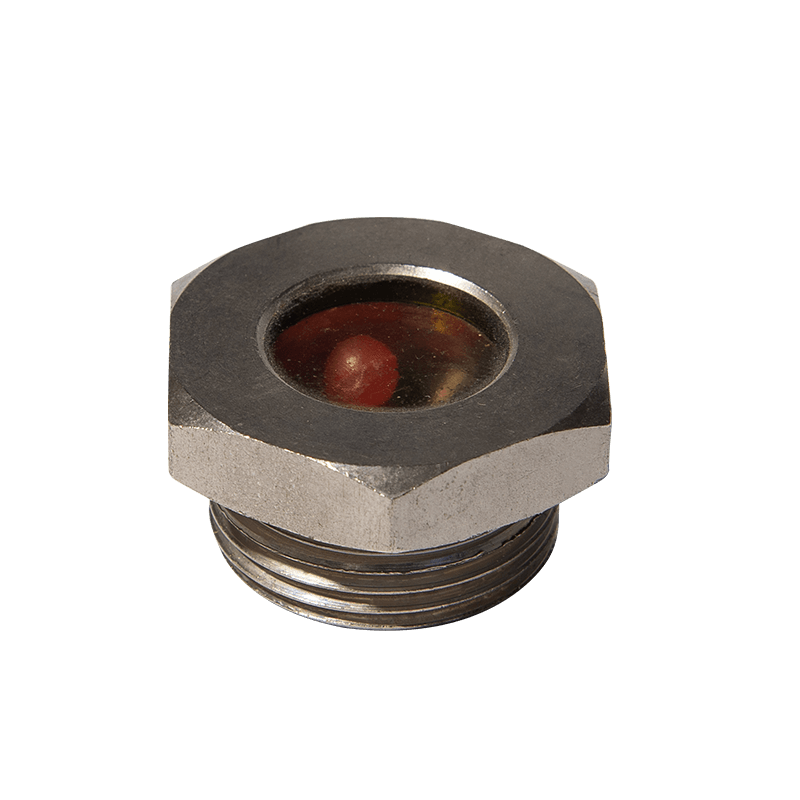

READ MOREIron Oil Level Sight Glass Supplier

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

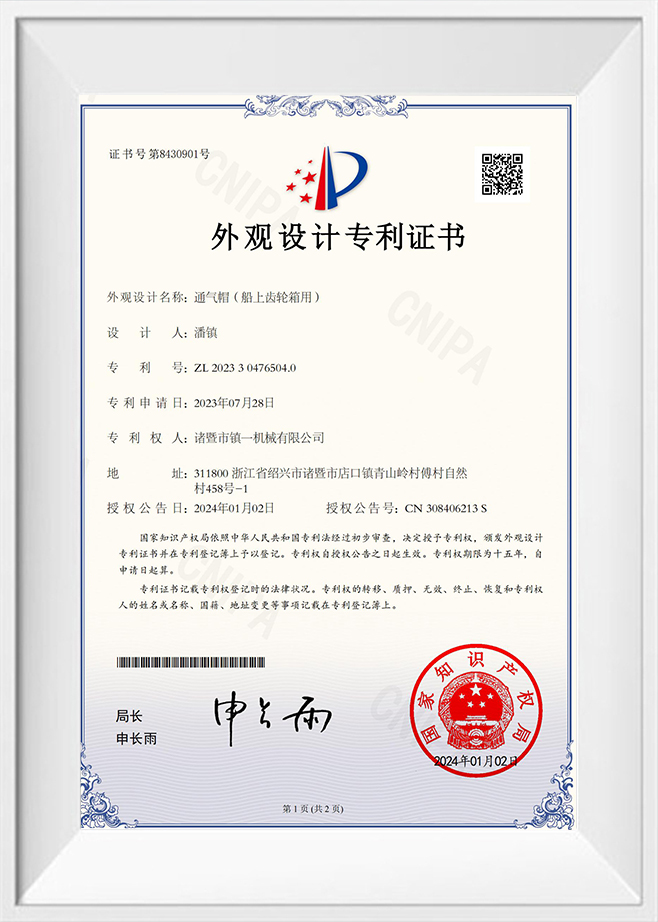

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

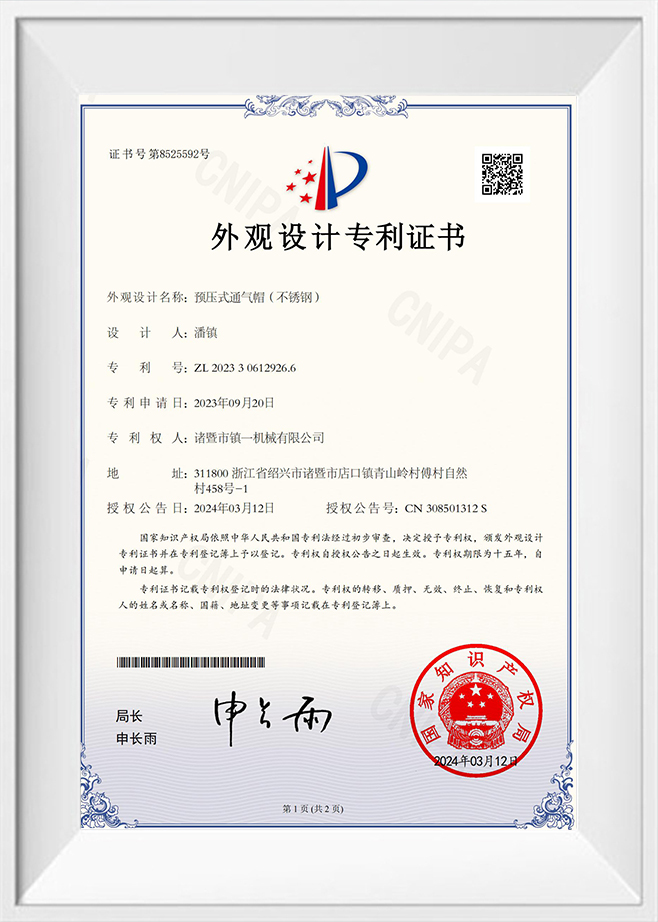

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

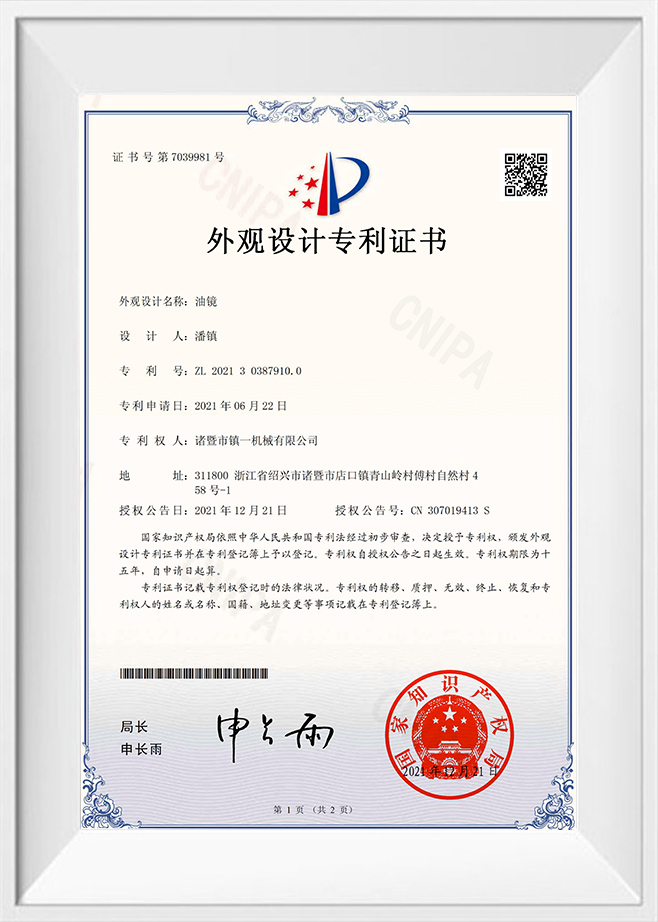

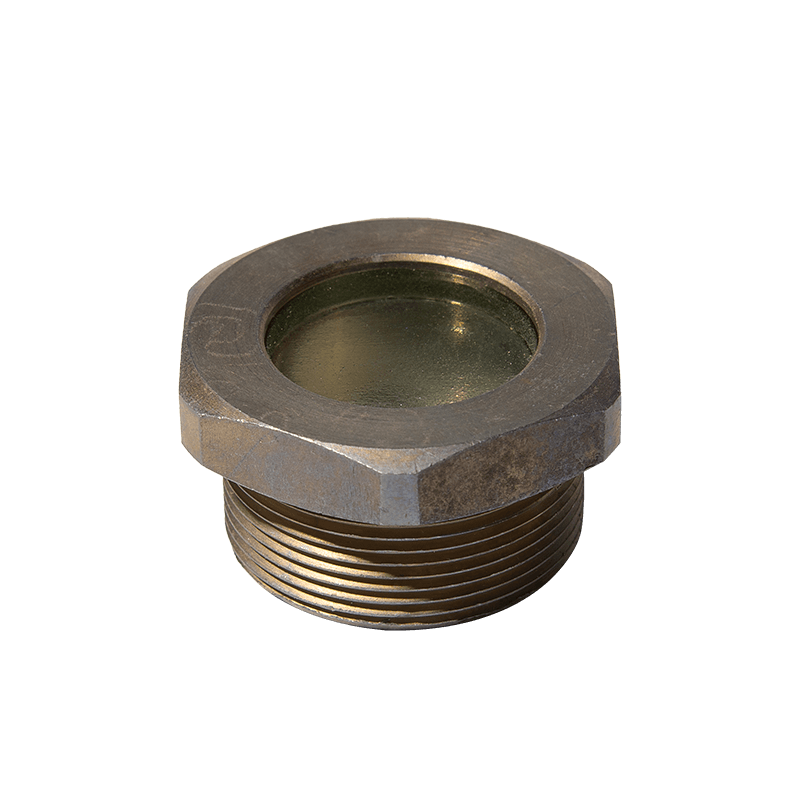

The main function of the iron oil level sight glass is to provide intuitive monitoring of the internal oil level of oil storage equipment (such as oil tanks, oil tanks, hydraulic systems, etc.). Since its establishment in 2004, our company has been deeply involved in the reducer, air compressor and other industries. As a comprehensive enterprise integrating R&D, production and sales, we have a deep understanding and rich practical experience in the importance of oil level monitoring.

Iron oil level sight glass Through the transparent window of the sight glass, the operator can instantly and clearly see the oil height in the oil storage equipment. The iron oil level sight glass produced by our company uses high-quality materials and exquisite craftsmanship to ensure a clear and undistorted field of view, providing operators with accurate and reliable oil level information.

Oil level sight glasses play a key role in our company's reducers, air compressors and other products, helping to ensure that the oil remains within a safe and effective operating range, avoiding equipment failures and safety hazards caused by too much or too little oil.

Our company is well aware of the importance of equipment maintenance, so our iron oil level sight glass is designed to be easy to observe and clean, so that operators can find out the oil consumption in time and arrange the time to replenish or replace the oil reasonably, so as to extend the service life of the equipment and reduce downtime. In addition to observing the oil level, our iron oil level sight glass can also indirectly reflect the quality of the oil. If the oil contains impurities or moisture, it may leave marks on the sight glass, prompting the operator to analyze or replace the oil to ensure the stable operation of the equipment.

In some of our products, the oil level sight glass can also be connected to the alarm system. When the oil level is lower than the safety threshold, the alarm is automatically triggered to remind the operator to take emergency measures to ensure production safety.

Our iron oil level sight glass adopts anti-corrosion, explosion-proof, high temperature or low temperature resistant materials to adapt to various harsh industrial environments and ensure accurate and reliable operation under various conditions.

As an important part of our product system, the iron oil level sight glass not only provides an intuitive means of oil level monitoring for oil storage equipment, but also provides strong support for improving equipment operation efficiency and ensuring production safety. Our company will continue to uphold the corporate philosophy of "innovation, quality, and service" and provide better products and services for the reducer, air compressor and other industries.

.jpg)