In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MORECarbon Steel Oil Level Sight Glass Supplier

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

Since its establishment in 2004, our company has been focusing on the reducer, air compressor and other industries for more than 20 years. As a comprehensive enterprise integrating R&D, production and sales, we have provided the market with many high-quality products and services with rich industry experience and deep technical strength.

Our product range is wide, covering aluminum alloy oil gauges, oil mirrors, oil level mirrors, vent caps, exhaust caps, air filters, pressure vent caps, oil cups, positioning oil cups, L-type oil cups and other pump accessories, reducer accessories, air compressor accessories and various hydraulic oil tank accessories. These products are widely used in various industrial equipment, providing a strong guarantee for the stable operation of the equipment.

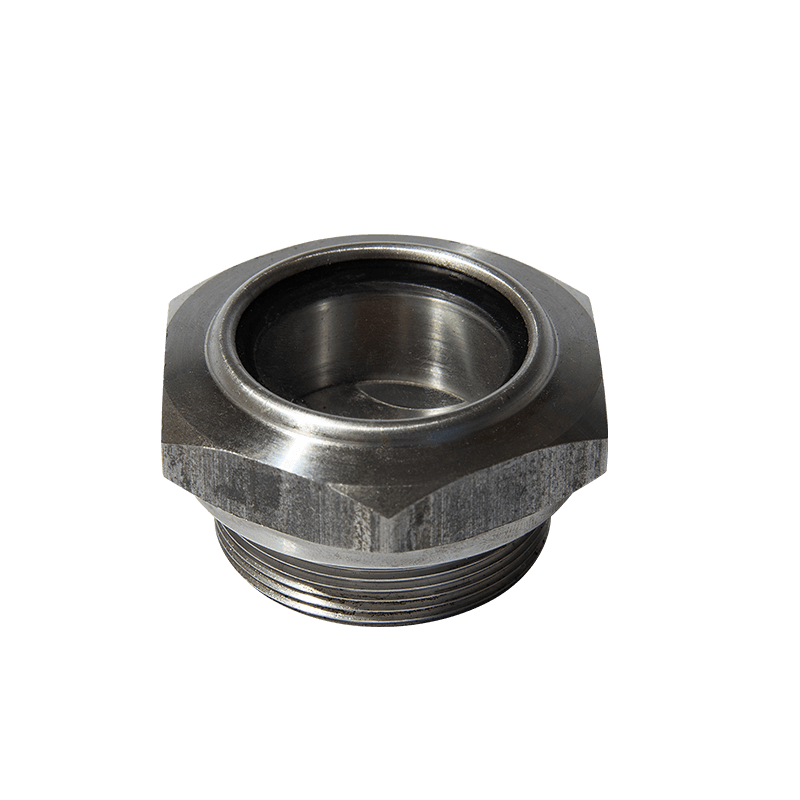

Carbon steel oil level sight glass, as an industrial observation device, is mainly used to monitor and observe the height and state of oil in oil storage tanks, oil tanks or other liquid containers. It is made of high-quality carbon steel material, with high strength, corrosion resistance, high temperature resistance and other characteristics, suitable for various harsh industrial environments. Through the oil level sight glass, the operator can intuitively understand the level changes of the liquid medium to ensure the safe operation of the equipment and the reasonable management of the liquid.

The carbon steel oil level sight glass is made of high-quality carbon steel material, which has good mechanical properties and corrosion resistance, and can operate stably for a long time in harsh environments such as high temperature, high pressure, and corrosive media. It is equipped with a high-transmittance glass or transparent material observation window to ensure that the operator can clearly observe the liquid level changes and improve the monitoring accuracy. The use of advanced sealing technology and materials ensures that the sight glass will not affect the normal operation of the equipment due to medium leakage during installation and use. The structure is reasonably designed and easy to install. It can be customized according to the specific needs of the user to meet the installation requirements of different liquid storage containers. The sight glass is easy to disassemble and clean, which is convenient for users to perform daily maintenance and maintenance of the equipment.

Carbon steel oil level sight glass is widely used in the liquid level monitoring of oil storage tanks, oil tanks, reactors, boilers and other equipment in the petroleum, chemical, electric power, metallurgy, food, pharmaceutical and other industries. It is suitable for the observation of various liquid media, such as lubricating oil, fuel oil, coolant, chemical raw materials, etc.

According to the type, temperature, pressure, corrosiveness and other factors of the medium, choose the appropriate carbon steel material and sealing material. According to the size of the liquid storage container and the range of liquid level changes, select the appropriate observation window size to ensure that the liquid level changes can be clearly observed. According to the structure and installation location of the liquid storage container, select the appropriate installation method, such as flange connection, threaded connection, etc. According to actual needs, additional functions such as drain valves and lighting devices can be considered to improve the practicality and convenience of the equipment.

.jpg)