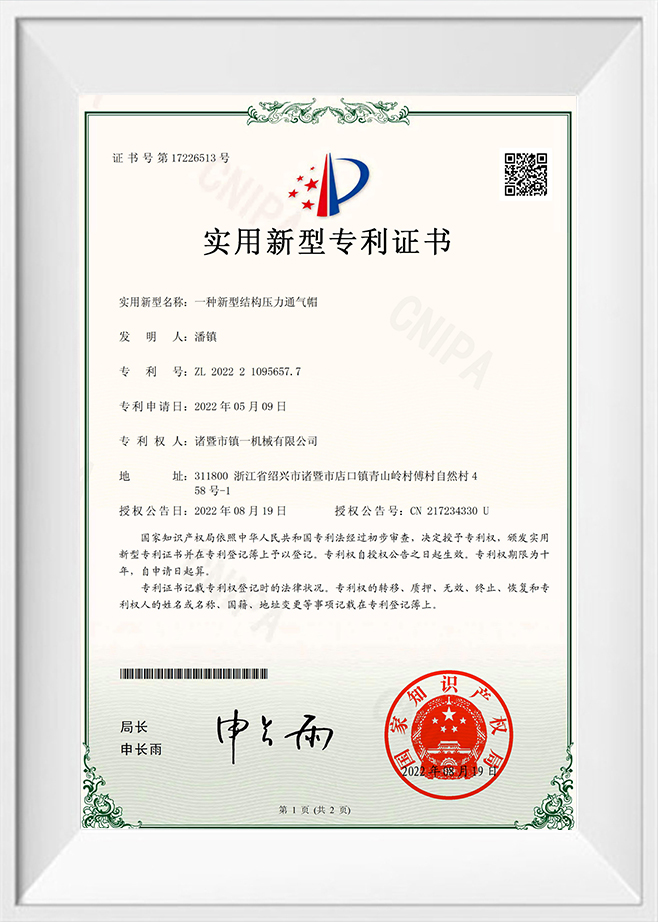

In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREBrass Oil Level Sight Glass Supplier

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

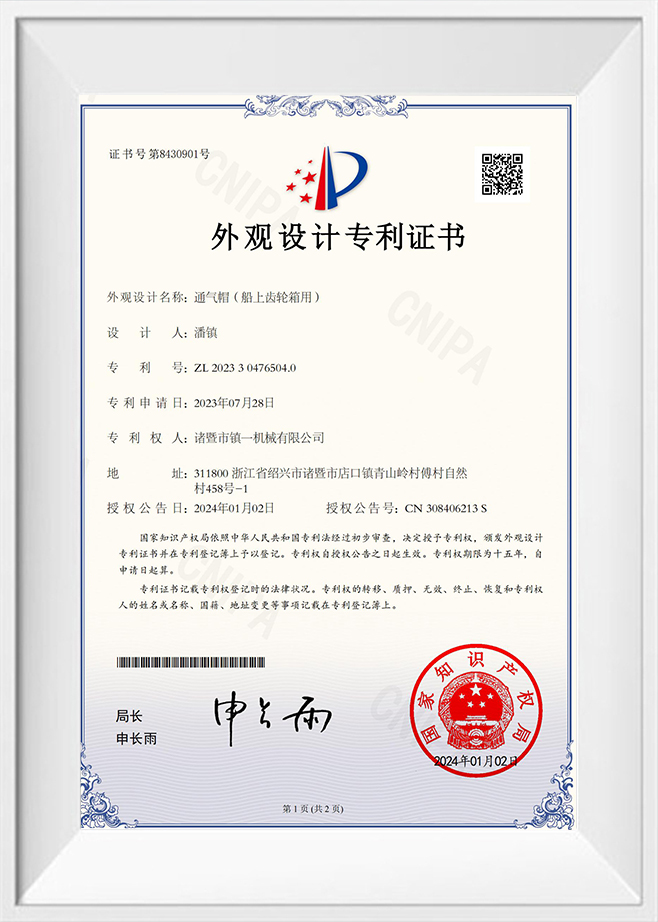

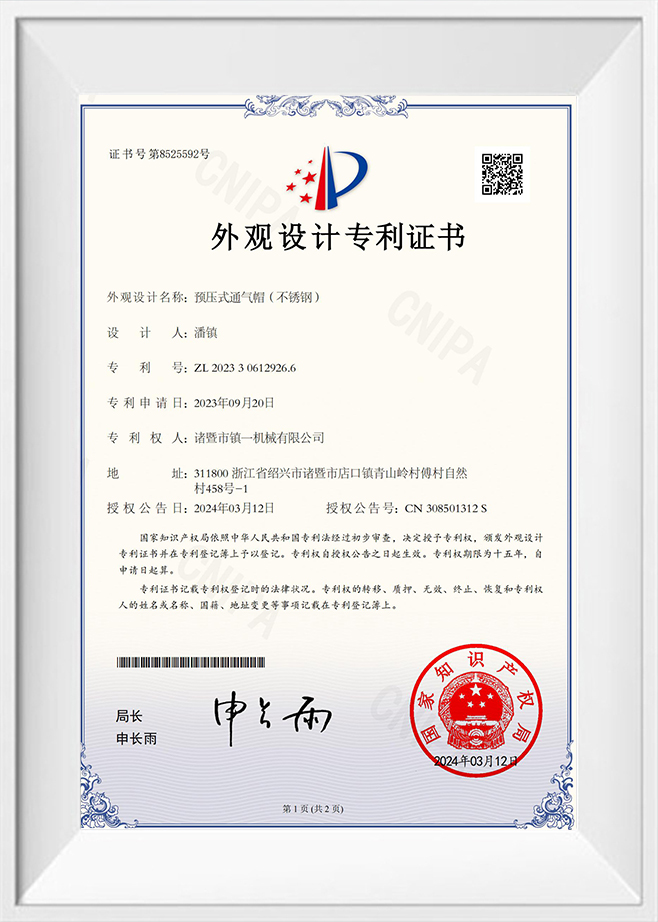

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

Our company is a high-tech enterprise focusing on the research, development, production and sales of pump accessories, reducer accessories, air compressor accessories and various hydraulic oil tank accessories. We are committed to providing high-quality and high-performance product solutions for global industrial users, covering aluminum alloy oil gauges, oil mirrors, oil level mirrors, vent caps, exhaust caps, air filters, pressure vent caps, oil cups, positioning oil cups, L-type oil cups and other series, which are widely used in petroleum, chemical, electric power, food processing, machinery manufacturing and other industries. With excellent product quality, professional technical services and perfect after-sales service system, we have won the unanimous trust and praise of domestic and foreign customers.

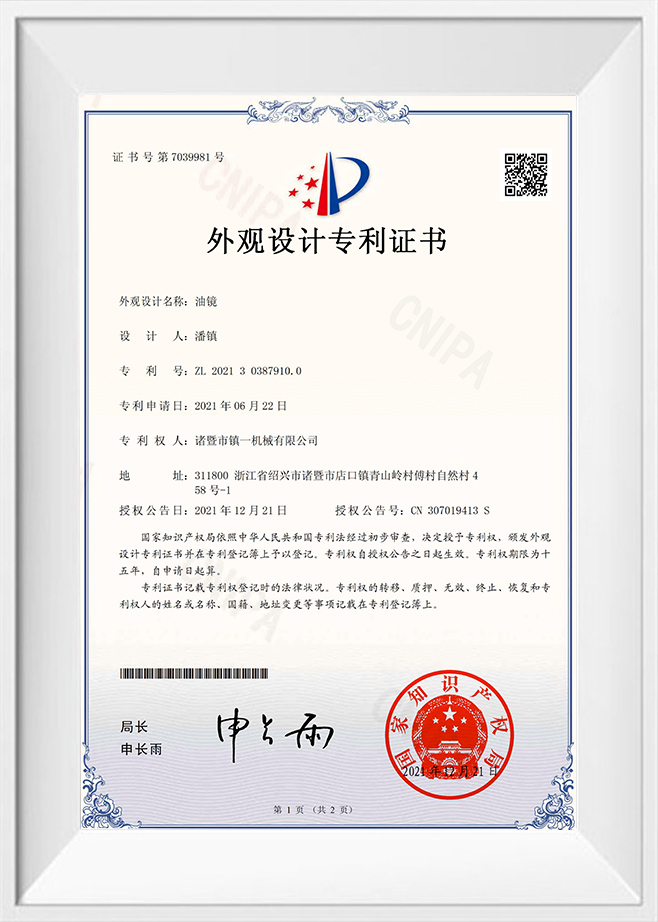

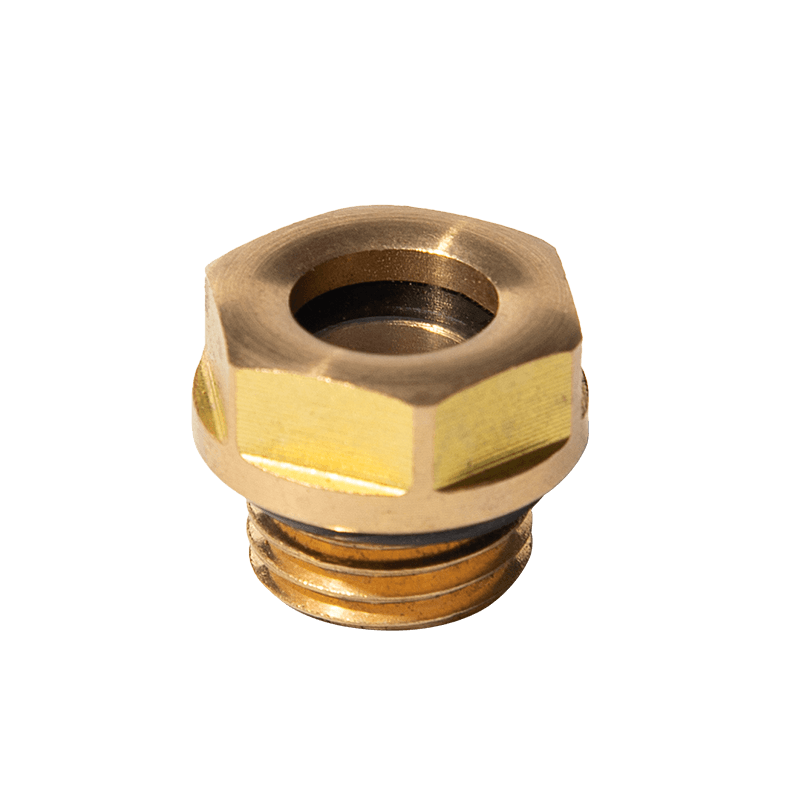

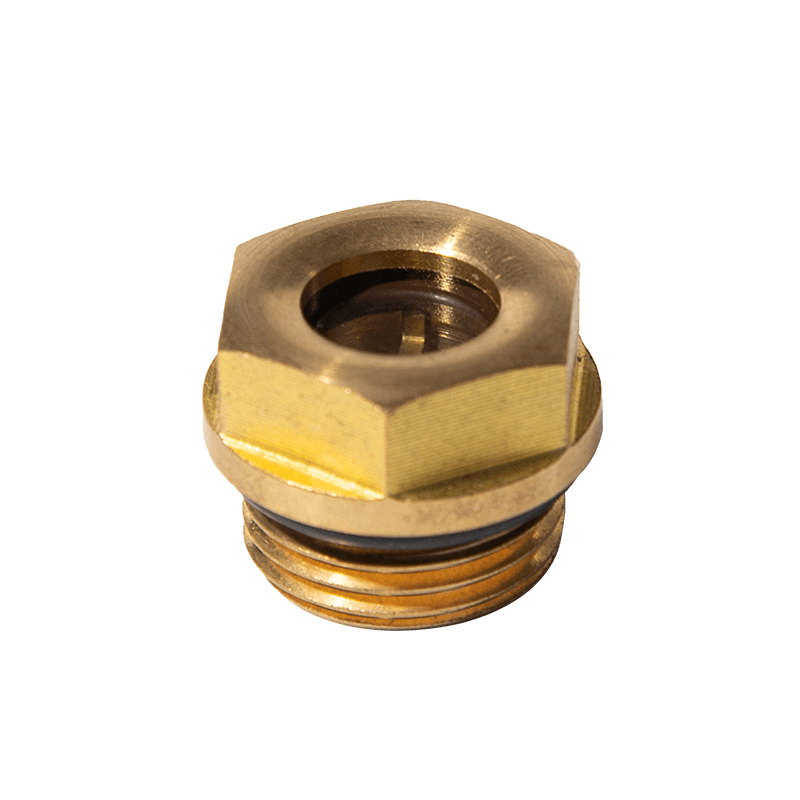

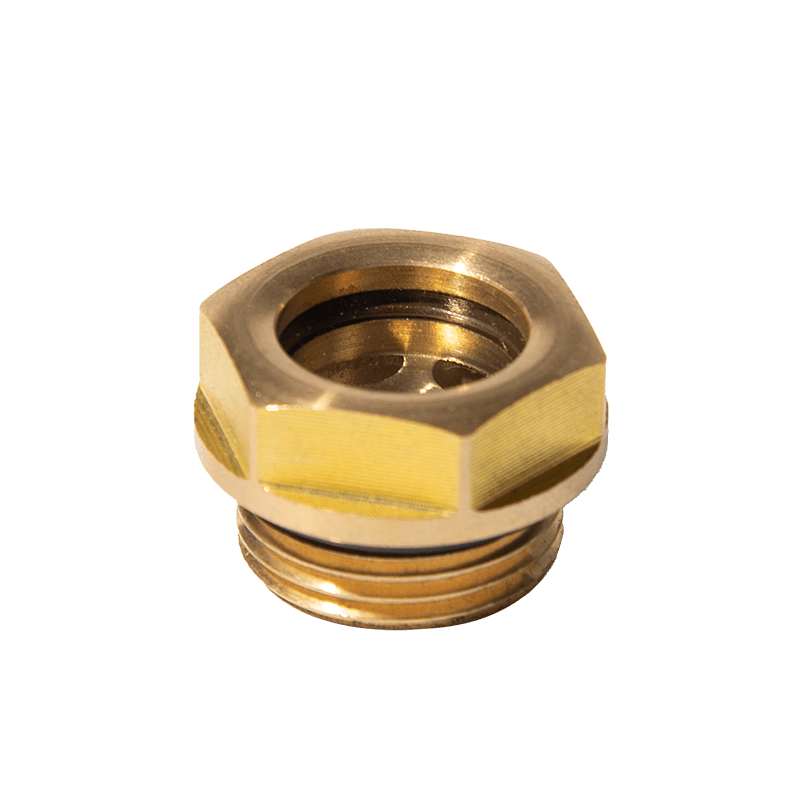

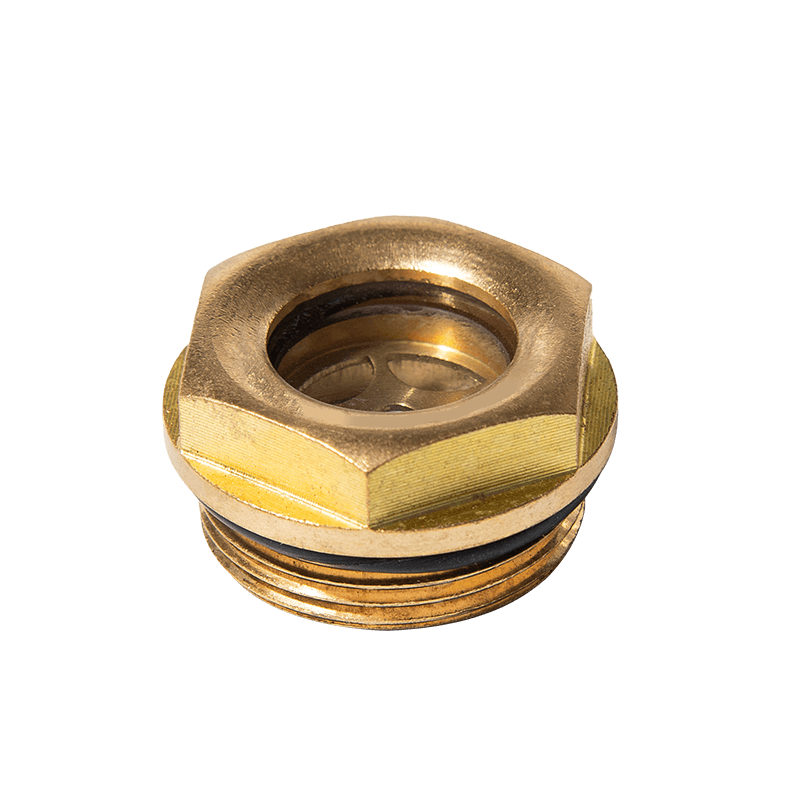

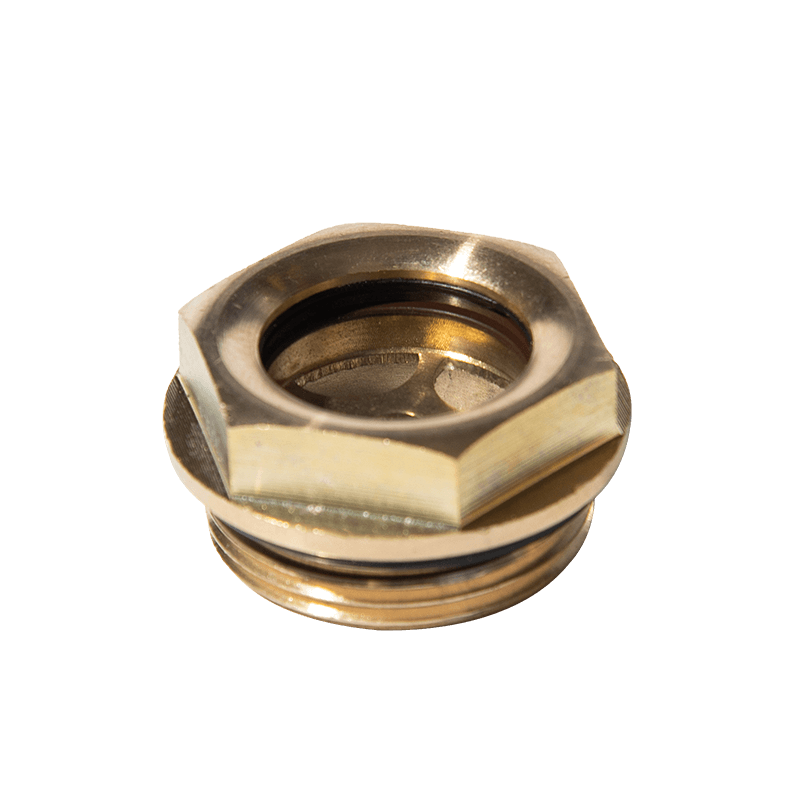

Brass oil level sight glass, as one of our company's core products, is widely used in oil level monitoring in industrial equipment. The use of high-quality brass as the main material ensures the corrosion resistance and durability of the sight glass, and at the same time has good thermal conductivity and electrical conductivity, which is suitable for a variety of working environments. Through the transparent window design, the operator can clearly observe the horizontal position of the oil, thereby ensuring the normal operation and maintenance of the equipment.

The high-purity brass we choose is an ideal material for manufacturing oil level sight glasses. Brass has become the first choice in many industrial applications due to its unique metal properties, such as good ductility, high strength and excellent corrosion resistance. In our production process, high-purity brass undergoes a precision casting process to ensure the sturdiness of the main structure of the sight glass. Subsequently, through fine processing, the durability and corrosion resistance of the sight glass are further improved. This material selection and processing process make our oil level sight glass particularly suitable for long-term use in humid and corrosive environments, effectively resisting the erosion of various harsh environments and ensuring the stable operation of the equipment.

In order to ensure that operators can accurately and clearly observe the oil level, we use high-transmittance, temperature-resistant, and aging-resistant glass or transparent plastic materials as the sight glass window. These materials not only have excellent light transmission performance and can provide a clear view under different lighting conditions, but also have excellent temperature resistance and aging resistance, ensuring the long-term stability and reliability of the window. In addition, our window design also fully considers the explosion-proof performance. Even in extreme cases, it can effectively prevent explosion accidents caused by excessive oil pressure, providing a strong guarantee for the safe operation of the equipment.

Sealing performance is one of the important indicators to measure the quality of oil level sight glasses. We are well aware of its importance, so we use advanced sealing technology, such as O-rings, gaskets, etc., to ensure that there is no leakage at the connection between the sight glass and the container. These seals not only have good elasticity and wear resistance, but also can maintain a stable sealing effect under various temperature and pressure conditions. Through this design, we effectively prevent the overflow of oil and the entry of impurities, maintain the purity of the oil and the normal operation of the equipment.

In order to facilitate the installation and use of users, we specially designed standard flange interfaces or threaded interfaces. These interfaces not only meet international general standards, but also have good interchangeability and versatility, so that our oil level sight glasses can be easily and quickly connected with various liquid storage containers. This design not only reduces installation time and cost, but also improves the overall performance and reliability of the equipment. Users can easily install and remove the sight glass without complicated modifications or adjustments, which brings great convenience to the maintenance and management of the equipment.

Our oil level sight glasses have been widely used in many industries such as petroleum, chemical, electric power, and food processing due to their excellent performance and wide applicability. Whether it is monitoring the level of lubricating oil, fuel or coolant, our oil level sight glasses can provide accurate and reliable monitoring results. At the same time, we can also provide customized solutions according to the specific needs and working environment of customers to meet the special requirements of different industries and application scenarios.

.jpg)