In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREStainless Steel Oil Cup Supplier

information to be updated

information to be updated

-

-

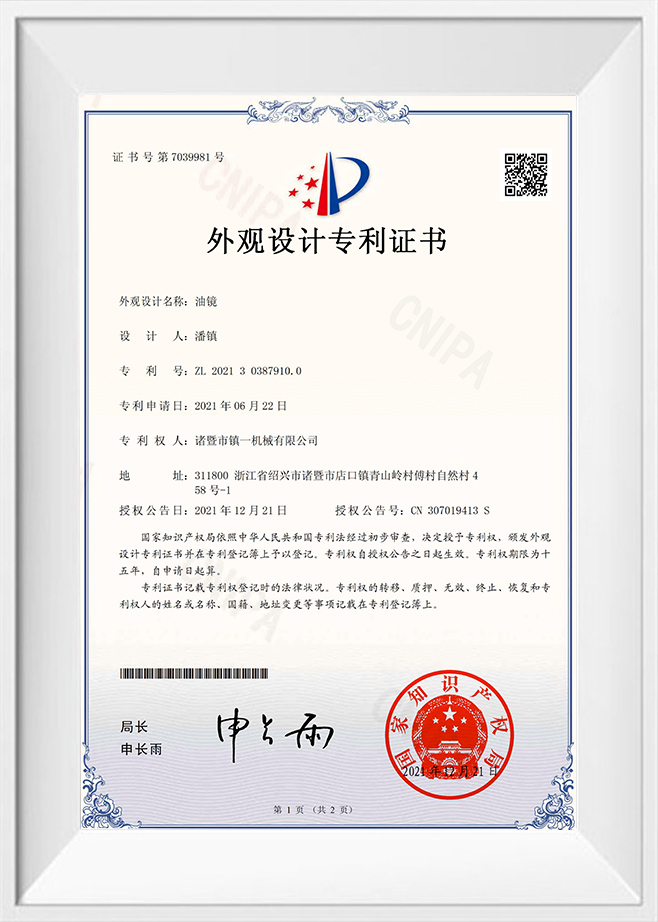

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

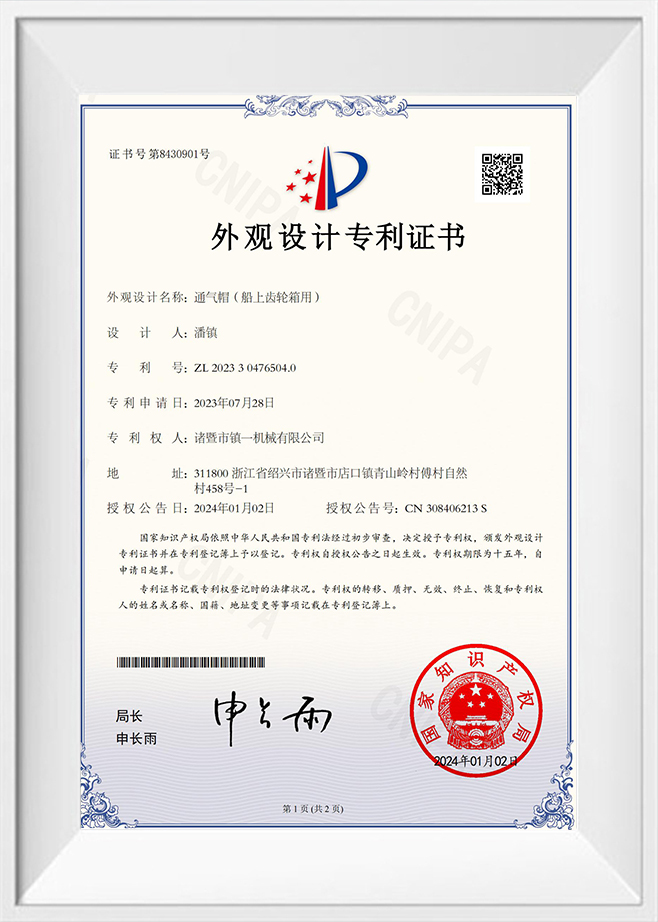

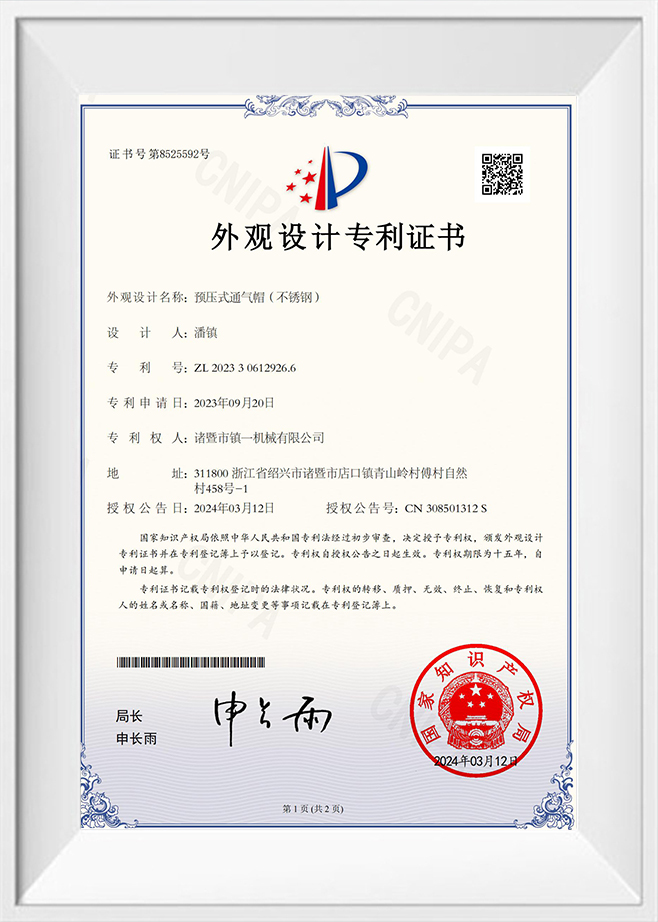

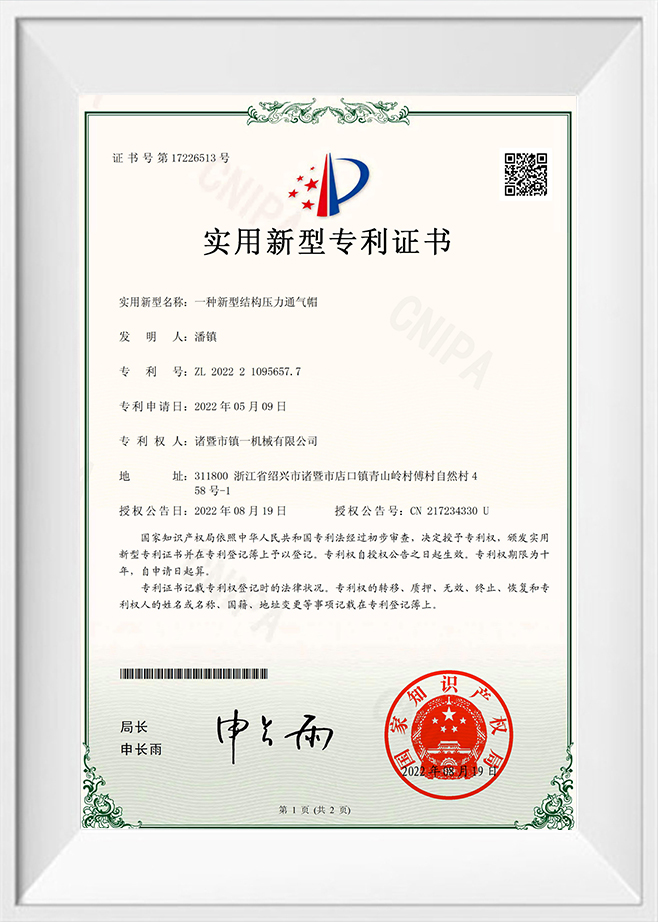

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

In complex hydraulic systems, the oil cylinder is a key actuator, and its performance directly affects the stability and efficiency of the system. In order to ensure the smooth operation of the oil cylinder, reduce wear and extend the service life, the cylinder seats at both ends of the oil cylinder are usually equipped with oil cups to continuously and evenly provide lubricating oil to the groove of the copper sleeve in the cylinder seat. As a manufacturer specializing in the manufacture of stainless steel oil cups, we are committed to providing customers with high-quality, durable and high-performance lubrication solutions.

Stainless steel material uses high-quality stainless steel as the main material of the oil cup, which not only gives the oil cup extremely high corrosion resistance and wear resistance, but also ensures its long-term stability in harsh working environments. Stainless steel can effectively resist the erosion of chemicals in the lubricating oil and keep the oil pure. At the same time, its excellent mechanical properties ensure the strength and durability of the oil cup.

The stainless steel oil cup adopts a precise manufacturing process to ensure the close fit between the various components, thereby improving the sealing performance and lubrication efficiency of the oil cup. The design of the oil cup fully considers the convenience of installation and maintenance, allowing users to easily install, disassemble and clean.

In order to meet the lubrication needs of different oil cylinders, we have designed an adjustable oil outlet. Users can adjust the oil output according to actual conditions to ensure that the lubricating oil can accurately and evenly enter the groove of the copper sleeve in the cylinder seat to achieve the best lubrication effect.

During the operation of the cylinder, as the piston rod reciprocates, the lubricating oil in the stainless steel oil cup is slowly released into the groove of the copper sleeve in the cylinder seat through the oil outlet under the action of gravity and/or system pressure. This lubricating film can effectively reduce the direct contact between metal parts, reduce the friction coefficient, reduce wear, and take away the heat generated by friction to keep the system temperature stable.

The stainless steel material makes the oil cup extremely durable and fatigue-resistant, and it can maintain stable performance even in harsh working environments. By precisely controlling the supply of lubricating oil, the stainless steel oil cup can ensure continuous and uniform lubrication inside the cylinder, thereby improving work efficiency and extending the service life of the equipment. The design of the oil cup fully considers the convenience of maintenance, and users can easily clean and replace it, reducing maintenance costs and time losses.

.jpg)