In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MORECarbon Steel Oil Cup Supplier

information to be updated

information to be updated

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

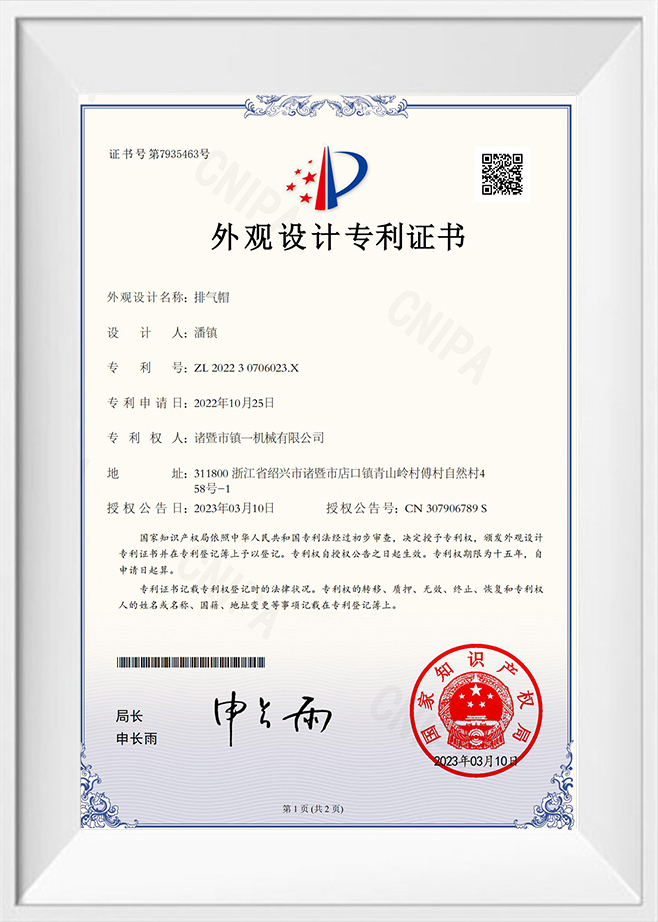

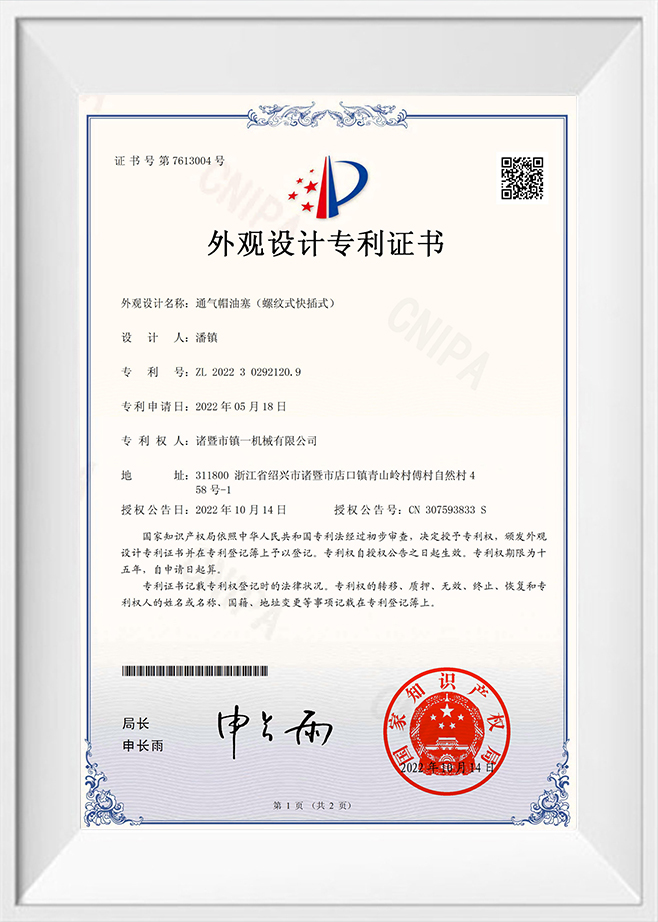

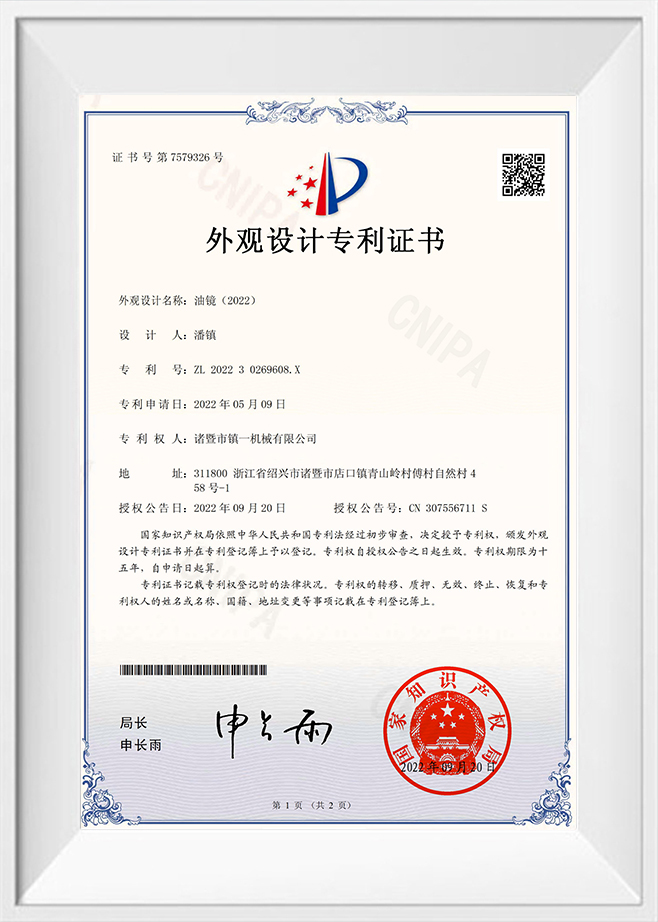

Since its establishment in 2004, our company has been focusing on the reducer, air compressor and other industries for more than 20 years. As a comprehensive enterprise integrating R&D, production and sales, we are committed to providing customers with high-quality and high-performance hydraulic oil tank accessories and related products. Our product range is wide, covering aluminum alloy oil gauges, oil mirrors, oil level mirrors, breather caps, exhaust caps, air filters, pressure breather caps, oil cups (including carbon steel oil cups), positioning oil cups, L-type oil cups and other pump accessories, reducer accessories, air compressor accessories and hydraulic oil tank accessories. These products are strictly quality controlled and tested to ensure their stability and durability.

Carbon steel oil cups play a vital role in hydraulic systems. It is mainly used on the cylinder seats at both ends of the cylinder, and through precise lubrication channels, the lubricating oil is sent into the groove of the copper sleeve in the cylinder seat, thereby ensuring the smoothness and wear resistance of the cylinder under long-term and high-load operation.

The main body of our carbon steel oil cup is made of high-quality carbon steel material, which is known for its high strength and good corrosion resistance. It can withstand the huge pressure generated by the hydraulic system at work and the harsh conditions in the external environment, ensuring the long-term stable operation of the oil cup.

The surface of the oil cup has been finely polished to give it a smooth and delicate appearance, which not only improves the beauty of the product, but also reduces the adhesion of dust and impurities, making it easy to clean and maintain daily. In order to prevent the oil cup from rusting during use, we use advanced anti-rust treatment technology. This treatment can form a protective film on the surface of the oil cup, effectively isolating moisture and oxygen in the air and extending the service life of the product.

The sealing structure of the oil cup is precisely designed and made of high-quality sealing materials. This sealing structure can ensure that the lubricating oil will not leak under high pressure, while preventing dust and impurities from entering the oil cup, keeping the lubrication system clean and efficient.

The oil cup is designed with reasonable lubrication channels, which are precisely calculated and optimized to ensure that the lubricating oil can accurately and evenly enter the groove of the copper sleeve in the cylinder seat. This design not only improves the lubrication effect, but also reduces the waste of lubricating oil and reduces operating costs.

In order to facilitate users to check and replenish lubricating oil at any time, we have equipped the oil cup with an intuitive oil level indicator. This device can be in the form of a transparent observation window or scale mark. The user can easily understand the amount of lubricating oil in the oil cup by simply observing the window or reading the scale mark to ensure the normal operation of the lubrication system.

The fit between the oil cup and the cylinder seat is made of high-quality sealing material. This sealing material has good elasticity and wear resistance, and can maintain a tight fit during long-term use to prevent lubricating oil leakage and impurities from entering. At the same time, it can also adapt to working environments under different temperature and pressure conditions to ensure the stability and reliability of the oil cup.

.jpg)