In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREHydraulic Accessories Manufacturer

-

Hydraulic accessories

For a long time, gold, petroleum, mining, engineering, construction, chemical, machine tools, transportation, and other industries have provided suppo...

Hydraulic accessories

Product Description:

For a long time, gold, petroleum, mining, engineering, construction, chemical, machine tools, transportation, and other industries have provided supporting hydraulic equipment while providing high-quality domestic spare parts for the introduction of advanced equipment. The company has high-quality product design, technology, manufacturing, testing, marketing, management, and other types of talent complete manufacturing equipment, advanced testing instruments, and a reliable quality assurance system. Our products are all kinds of filters, oil filter series, air filter series, return oil, oil suction filter series, level meters, level control relays, pressure gauge switches, combination seal gaskets, oil filter trucks, and other products, but also for customers to design and manufacture all kinds of non-standard hydraulic parts.

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

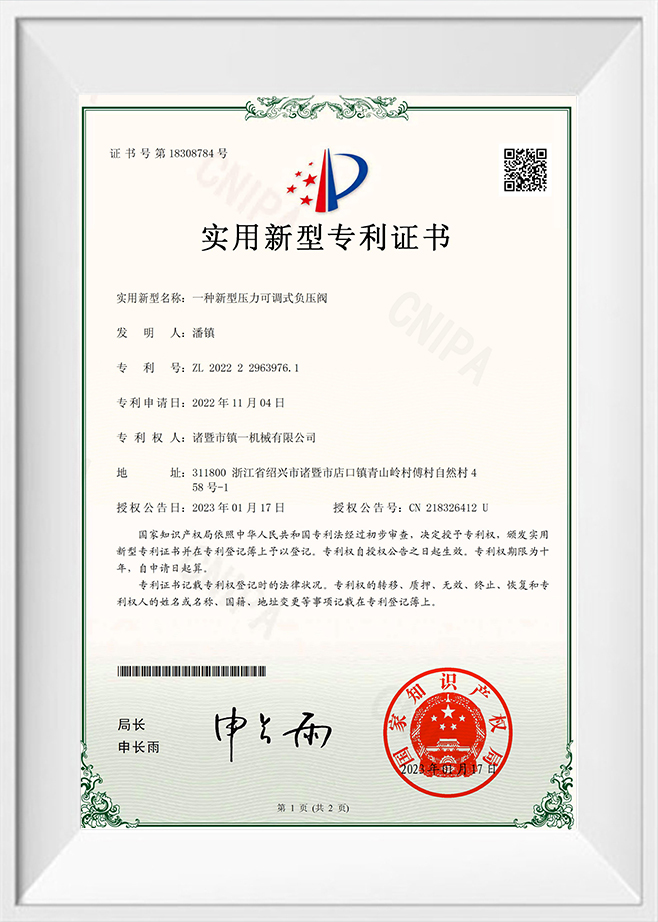

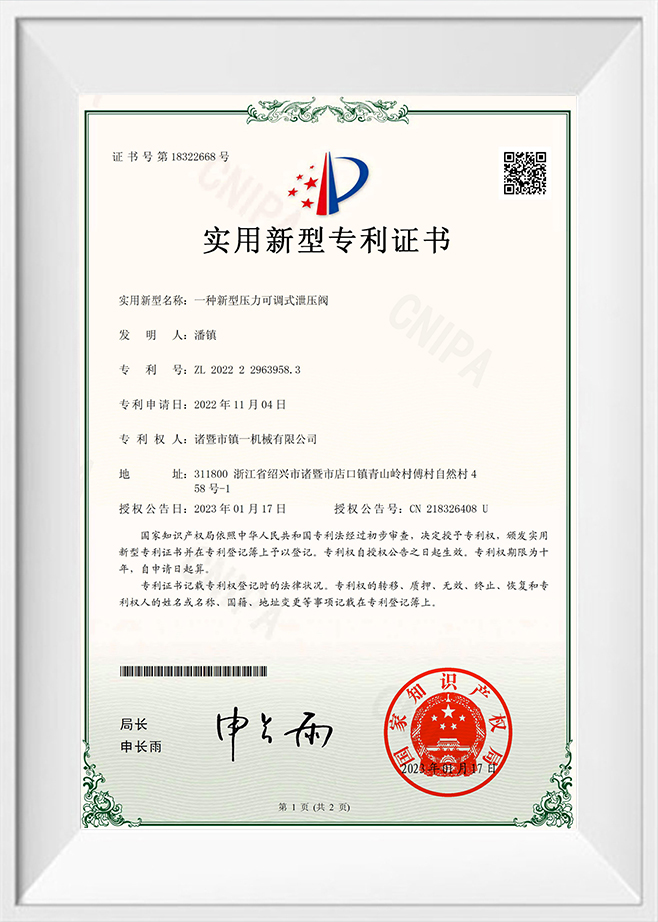

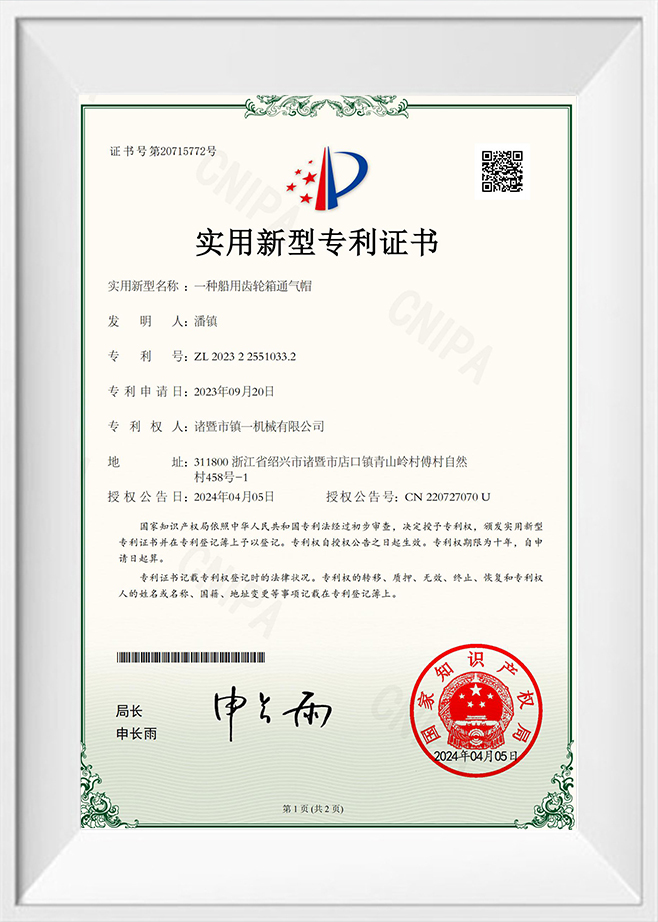

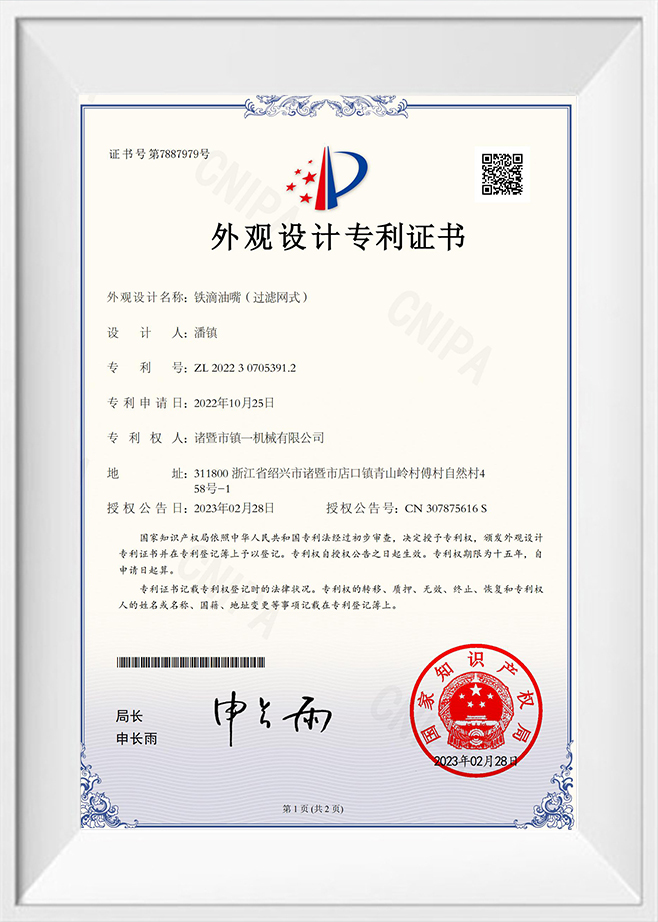

Our company is a well-known enterprise focusing on the production of hydraulic accessories and related accessories such as pumps, reducers, and air compressors. We have a skilled and experienced team, including 5 professional technicians and nearly 30 operators of various types. With advanced production technology and strict quality control, our products have won wide recognition and praise in the market.

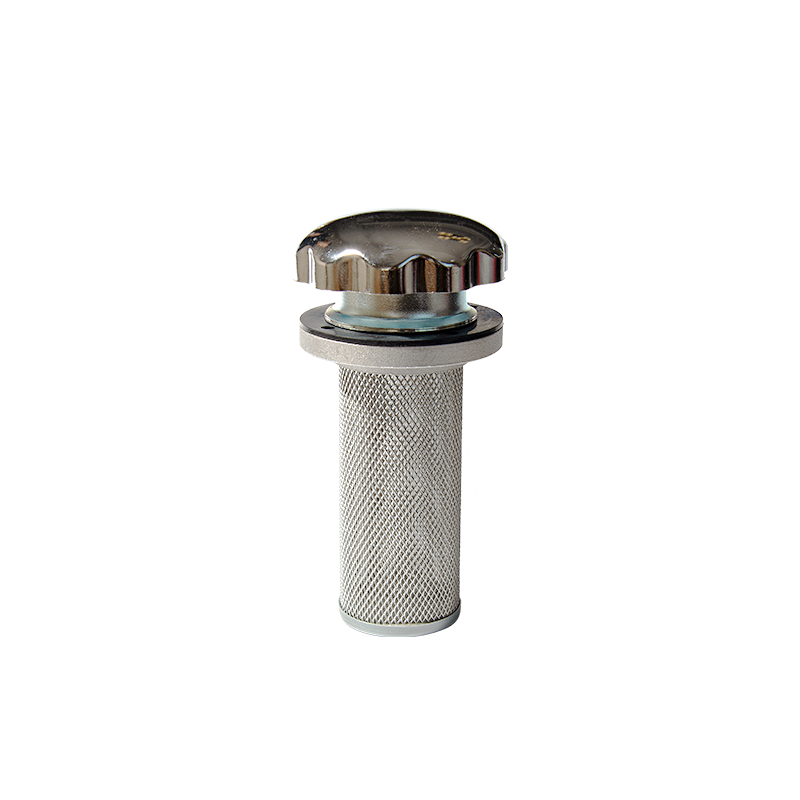

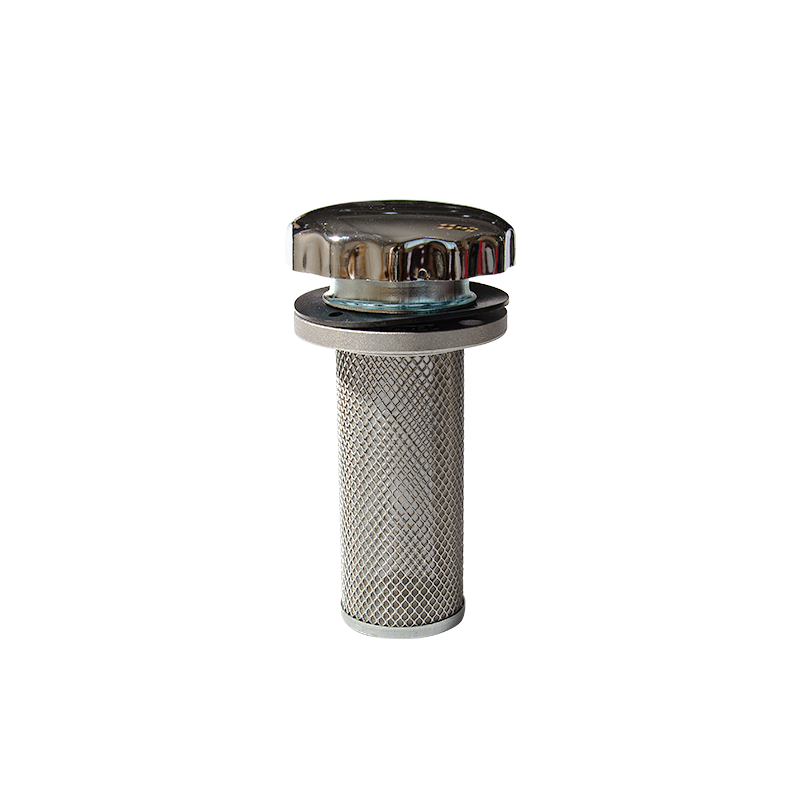

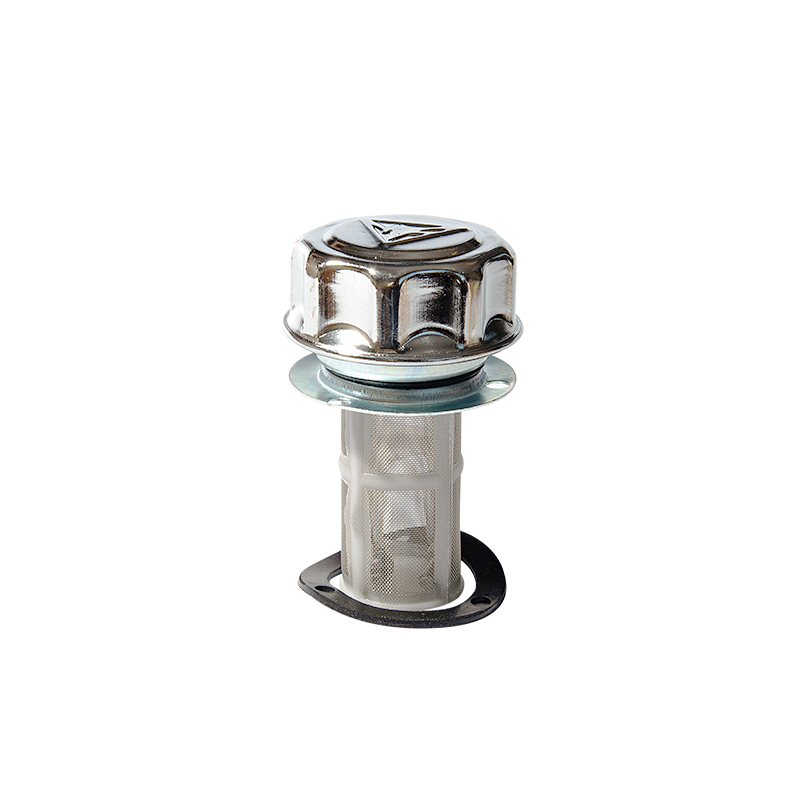

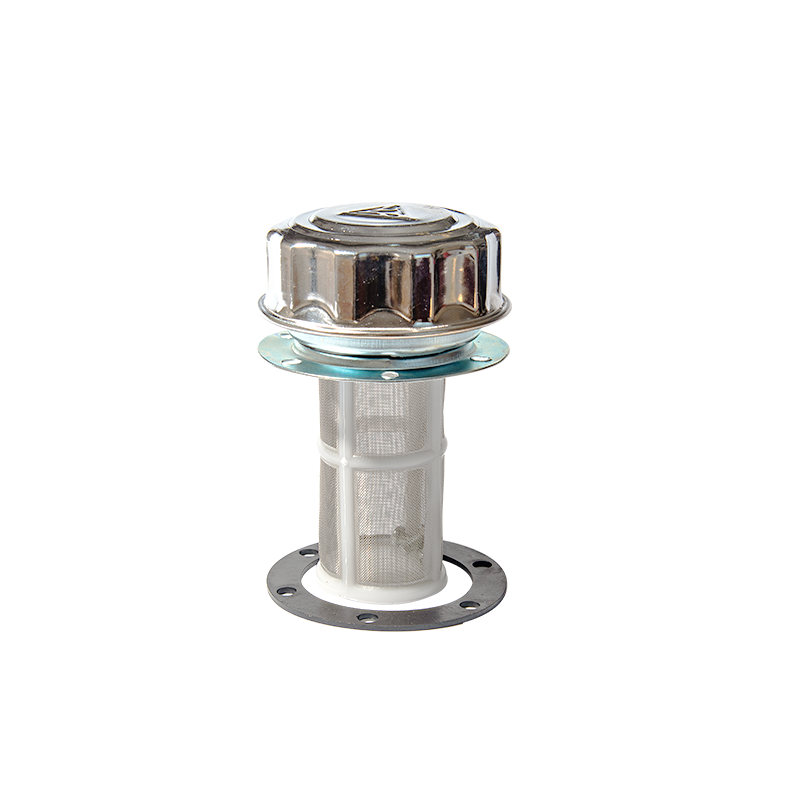

Our product range covers a series of pump accessories, reducer accessories, air compressor accessories, and hydraulic oil tank accessories such as aluminum alloy oil gauges, oil mirrors, oil level mirrors, breather caps, exhaust caps, air filters, pressure breather caps, oil cups, positioning oil cups, L-type oil cups, etc. These products not only have excellent performance and reliable quality, but also meet the diverse needs of different customers for products.

Hydraulic Accessories are an indispensable part of the hydraulic system. They work together to ensure the normal and efficient operation of the hydraulic system. These accessories not only provide various functions required by the system, but also ensure the stability and safety of the system.

Hydraulic cylinder

Function: The hydraulic cylinder is the main actuator of the hydraulic system, which is used to convert hydraulic energy into mechanical energy to achieve linear reciprocating motion or swing.

Type: According to the different structures and working principles, hydraulic cylinders can be divided into piston type, plunger type and swing type.

Hydraulic pump

Function: The hydraulic pump is the power source of the hydraulic system, which is used to convert mechanical energy into hydraulic energy and provide the required working pressure and flow for the system.

Type: Common hydraulic pumps include gear pumps, vane pumps and plunger pumps, each with different characteristics and applicable scenarios.

Oil tank

Function: The oil tank is used to store hydraulic oil, and at the same time plays the role of heat dissipation, precipitation of impurities and separation of gases.

Design: The design of the oil tank should meet the system's requirements for oil cleanliness, temperature and capacity.

Oil pipe

Function: The oil pipe is used to connect various components in the hydraulic system and transmit hydraulic oil.

Material: The oil pipe is usually made of pressure-resistant and corrosion-resistant materials, such as steel pipes, rubber pipes and plastic pipes.

Filter

Function: The filter is used to filter impurities and particles in the hydraulic oil to prevent them from damaging the system.

Type: According to the different filtering accuracy and purpose, the filter can be divided into coarse filter, fine filter and return oil filter.

Pressure gauge

Function: Pressure gauge is used to measure and display the pressure value in the hydraulic system, helping users understand the operating status of the system.

Type: Pressure gauges are available in various types, including pointer type, digital type and electric contact type.

Flow meter

Function: Flow meter is used to measure and display the flow value in the hydraulic system, helping users monitor and adjust the flow of the system.

Type: Common flow meters include turbine flow meter, electromagnetic flow meter and ultrasonic flow meter.

Valve

Function: Valves are used to control the flow direction, pressure and flow of oil in the hydraulic system to realize various control functions of the system.

Type: There are many types of valves, including directional valves (such as reversing valves), pressure valves (such as overflow valves, pressure reducing valves) and flow valves (such as throttle valves, speed regulating valves).

.jpg)