In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MORE

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

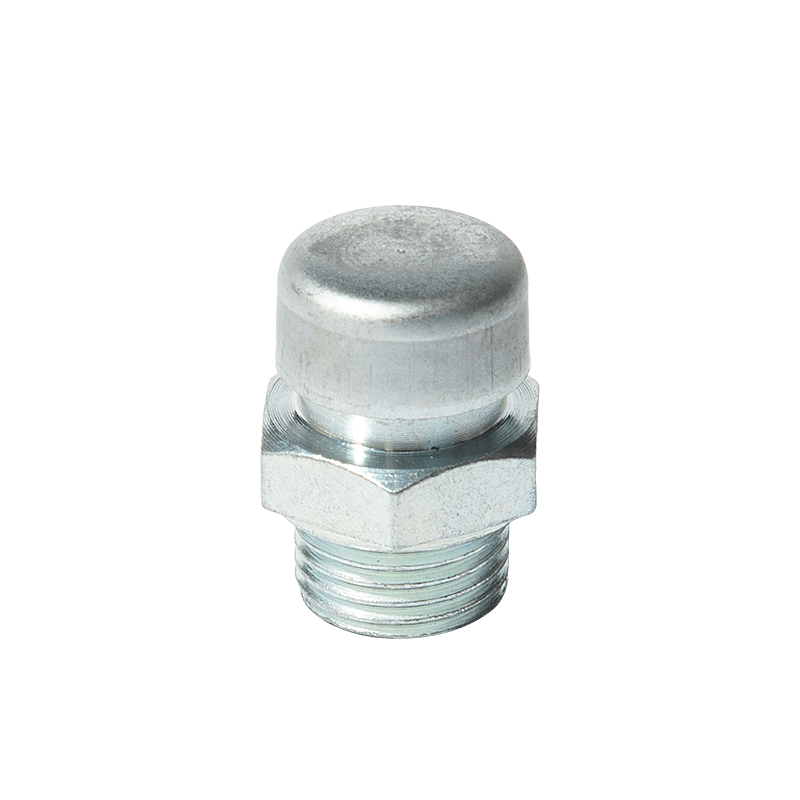

We select high-quality iron materials as the main raw material, combined with advanced heat treatment technology and surface treatment technology, such as galvanizing, spraying, etc., to effectively improve the corrosion resistance and service life of the valve body. At the same time, precision CNC machine tools are used to ensure the dimensional accuracy and surface finish of each component, thereby improving the overall performance and stability of the product.

The iron breathing valve has built-in precision pressure sensing elements, which can monitor the pressure changes inside and outside the tank in real time, and automatically open or close when necessary to ensure that the internal pressure of the tank is always within a safe range. This helps prevent tank rupture or leakage accidents caused by excessive pressure, as well as medium volatilization and contamination caused by low pressure.

In addition to the basic breathing function, our iron breathing valve is also equipped with multiple safety protection measures, such as explosion-proof discs, anti-blocking devices, etc., to cope with safety risks under extreme conditions. These designs not only enhance the overall safety of the valve, but also improve its adaptability in complex environments.

We are well aware that different industries and tank types have different specific requirements for breathing valves, so we provide comprehensive customized services. From the size of the valve, material selection to special functional requirements, we can tailor it according to the actual needs of customers to ensure that the product perfectly matches the customer's application scenario.

In order to facilitate customers' installation and use, we provide detailed installation guides and maintenance manuals. At the same time, our professional team also provides on-site installation guidance and technical support services to ensure that customers can easily complete the installation and daily maintenance of the breathing valve.

In addition to the traditional petroleum, chemical, pharmaceutical, food and environmental protection industries, our iron breathing valves are also widely used in new energy, shipbuilding, military industry and other fields. Whether it is a large oil storage tank, a chemical raw material tank or a biological agent storage container, our breathing valve can provide effective safety protection. Our manufacturer always adheres to the customer-centric service concept and is committed to providing customers with the best quality products and services. Whether you are looking for a standard iron breathing valve solution or need a customized special product, we will wholeheartedly meet your needs.

.jpg)