In modern industry and daily life, many devices and systems need to operate under high pressure. From large steam boilers to liquefied petroleum gas tankers around us, the consequences of uncontrolled...

READ MOREBrass Breather Valve Supplier

-

-

Maintaining an appropriate oil level is crucial for ensuring stable operation and extending the service life of various mechanical equipment. An oil level sight glass (as an oil level observation devi...

READ MORE -

In the chemical, petroleum, natural gas, and electronic educational equipment, conference equipment, and other fields, the safety of storage tanks is paramount. Breather valves (or venting valves) pla...

READ MORE -

The breather valve, a crucial component of a storage tank or container safety system, primarily protects the tank from damage caused by overpressure or vacuum. However, any mechanical equipment can ma...

READ MORE

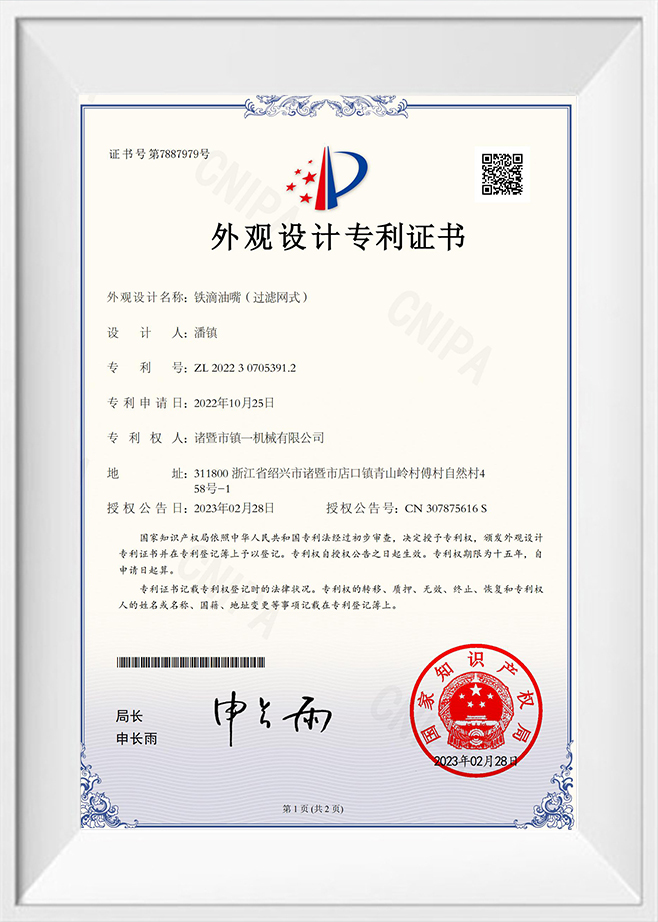

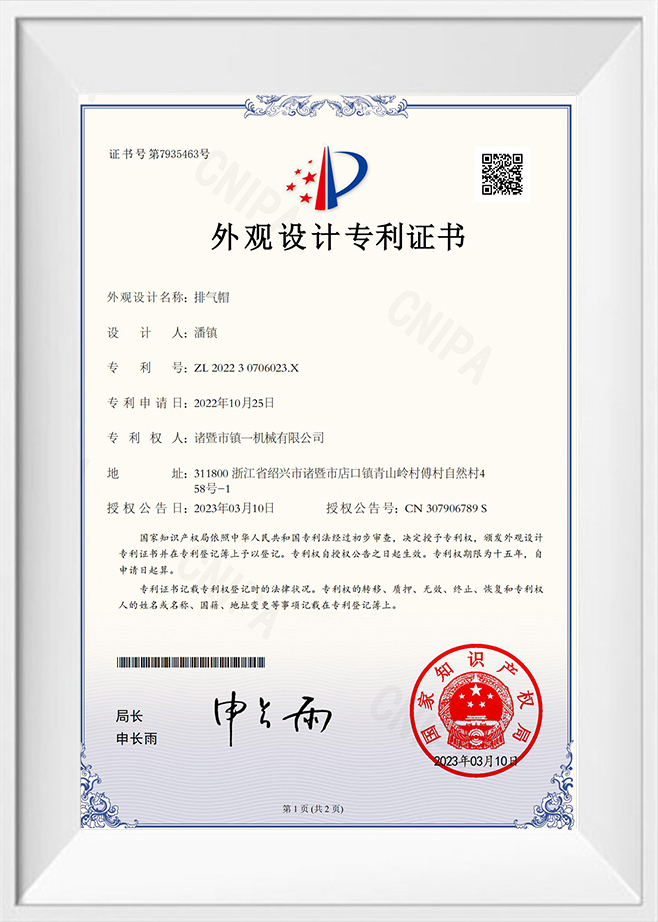

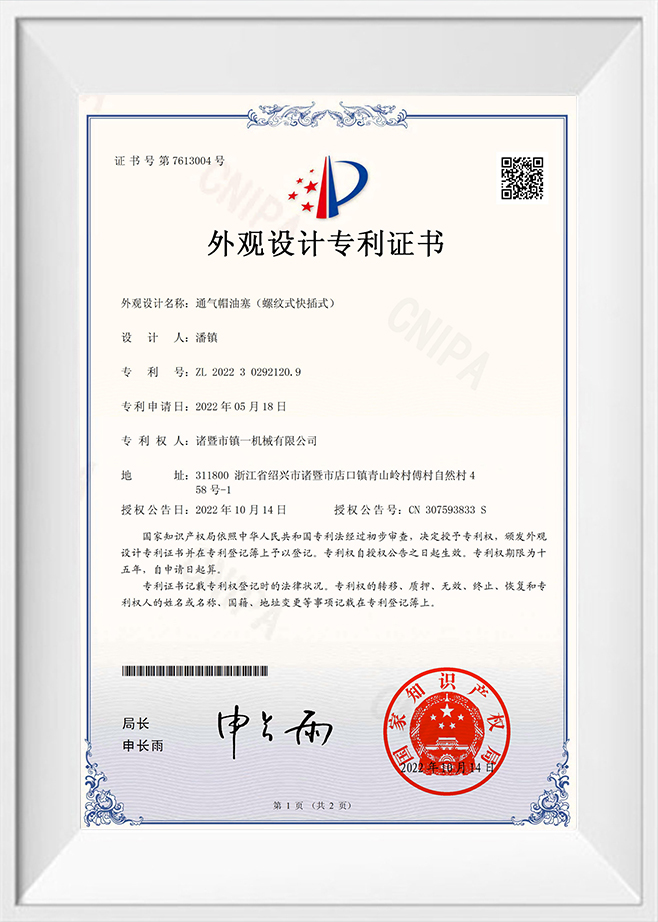

Our factory specializes in the production and supply of high-quality brass breathing valves. At the same time, as a well-known supplier of pump accessories, reducer accessories, air compressor accessories and hydraulic oil tank accessories in the industry, we have a rich product line and technical strength. We are a high-tech enterprise focusing on the research and development, production and sales of pump accessories, reducer accessories, air compressor accessories and hydraulic oil tank accessories. The company has a research and development team composed of 5 professional technicians, who rely on their deep industry experience and expertise to continuously promote product innovation and technological upgrading. In addition, we also have nearly 30 operators of various types, who are skilled in ensuring that every product can meet the highest standards.

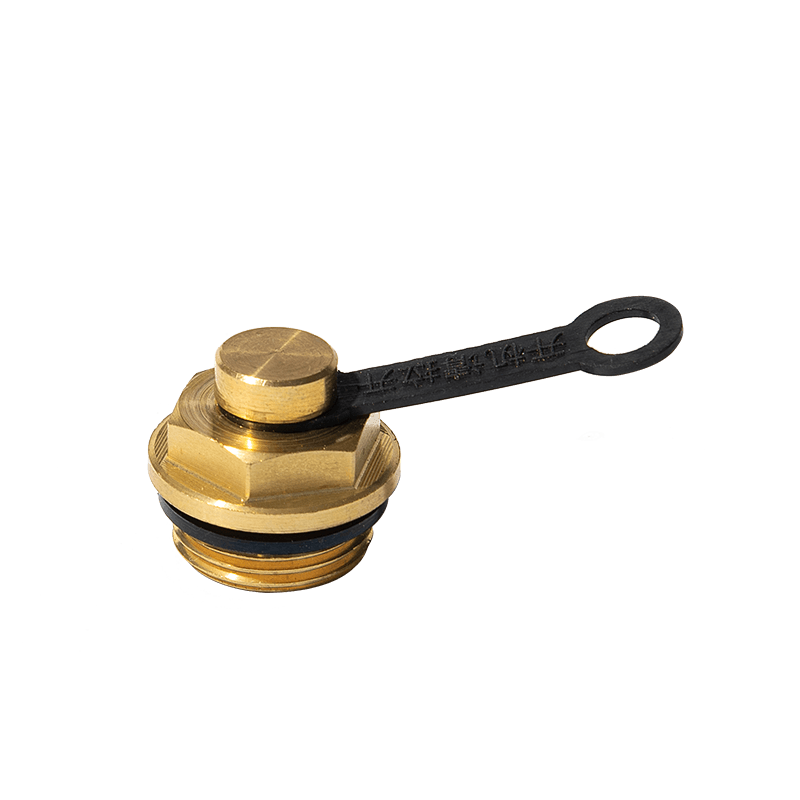

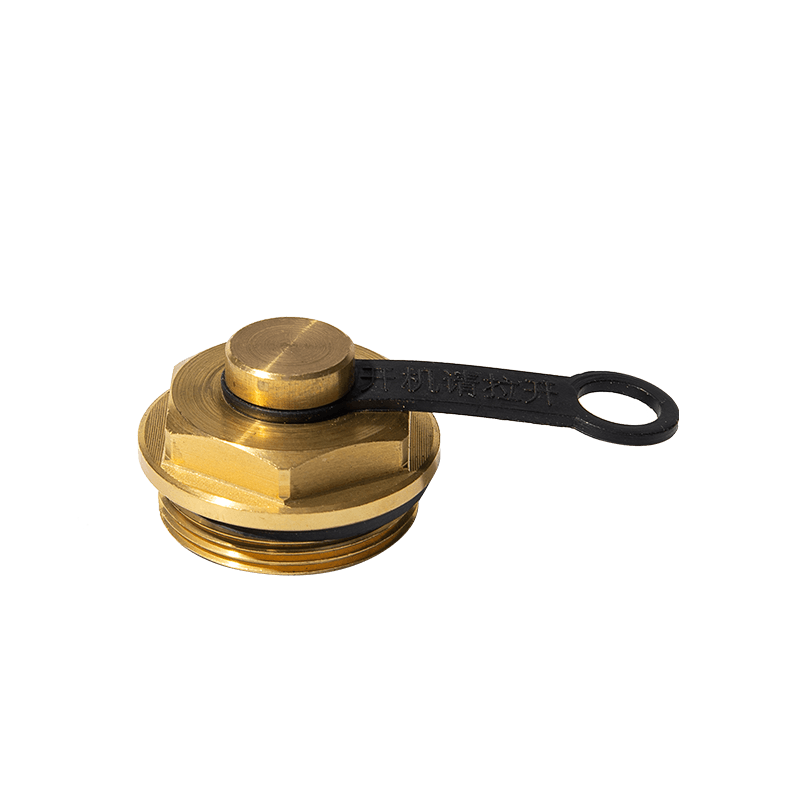

We select high-quality brass as the main casting material. This material not only has excellent mechanical properties, but also has good corrosion resistance, and can maintain the structural integrity and functional stability of the valve body in various harsh environments. The high density and strength characteristics of brass ensure that the breathing valve can withstand high pressure fluctuations and temperature changes in long-term operation, thereby extending the service life of the product. The valve body structure of the brass breathing valve has been precisely designed and optimized to ensure that it can still maintain excellent performance under high-load working conditions. The robustness of the valve body not only improves the durability of the product, but also reduces maintenance costs and downtime caused by valve body damage.

The brass breather valve is designed with precise breathing holes inside, which are precisely calculated and optimally laid out to ensure that air can flow freely under the pressure difference between the inside and outside. This design effectively balances the pressure inside and outside the equipment, avoiding equipment damage or performance degradation caused by pressure imbalance. Through the precise design of the breathing hole, the brass breather valve can respond to pressure changes in a very short time and quickly adjust the air flow to keep the pressure inside the equipment stable. This pressure balancing ability is essential to protect the normal operation of the equipment and extend its service life.

We use advanced sealing technologies, such as elastic sealing rings, metal sealing surfaces, etc., to ensure that the valve has good sealing performance when closed. These sealing technologies can effectively prevent gas or liquid leakage, thereby ensuring the safety and stability of the system. According to the needs of the application environment, we select suitable sealing materials, such as materials with oil resistance, high temperature resistance, corrosion resistance and other characteristics, to ensure that the sealing performance can be fully utilized under different working conditions.

Strong anti-corrosion performance

Brass has natural antibacterial and anti-corrosion properties, which can effectively resist the erosion of water, air and other chemicals. This property enables brass breather valves to maintain excellent performance in humid and corrosive environments. The anti-corrosion performance of brass not only extends the service life of the breather valve, but also reduces the maintenance cost and downtime caused by corrosion. This is especially important for equipment that requires long-term stable operation.

Brass breather valves provide standard flange interfaces or threaded connections. This design allows users to quickly install and replace the breather valve according to actual needs. At the same time, the standard interface also facilitates the connection and integration with other equipment. Because the brass breather valve has a reasonable structural design and is easy to disassemble, users can easily maintain and maintain it. This reduces maintenance costs and improves the reliability and availability of equipment.

Brass breather valves are widely used in oil storage tanks, roof ventilation, sewage treatment, chemical containers and other scenarios due to their excellent performance and wide applicability. Whether in harsh industrial environments or in situations where high safety is required, brass breather valves can play an excellent role. We provide brass breather valves in various specifications and models to meet the needs of different customers. Whether for small devices or large systems, we have the right solution.

.jpg)