What is the purpose of a breather valve?

Breather valves play a vital role in industrial machinery, particularly enclosed equipment like reducers. Their primary purpose and function is to balance the air pressure inside and outside the equipment, thereby protecting the seals and internal components and ensuring stable and long-lasting operation.

Why use a breather valve?

During operation, mechanical equipment like reducers, especially in outdoor environments or during extended periods of continuous operation, can experience significant internal temperature increases. This high temperature can lead to two main problems:

- Lubricant vaporization and expansion: The lubricant inside the equipment vaporizes and expands into gas due to heat, causing a sharp increase in pressure within the housing.

- Gear mesh friction: Internal gear mesh friction also generates significant heat.

Because the interior of the housing is a relatively sealed space, the heat-expanding gas and oil vapor can increase internal pressure. If this pressure is not released, it can exert significant external forces on the housing's oil seals and joints, leading to the following serious consequences:

- Seal failure and leakage: The intense internal pressure can damage the oil seals, causing oil leaks from the housing, or damage the motor through the motor oil seal.

- Dry grinding and failure of internal components: Severe and excessive lubricant leakage can cause internal gears and bearings to "dry grind" due to lack of lubrication, leading to excessive temperature rise and ultimately failure of the gears and bearings, significantly shortening the machine's service life.

How Breather Valves Work and Their Value

To avoid these problems, a device is needed to safely release excess pressure within the housing. This is where breather valves come into play:

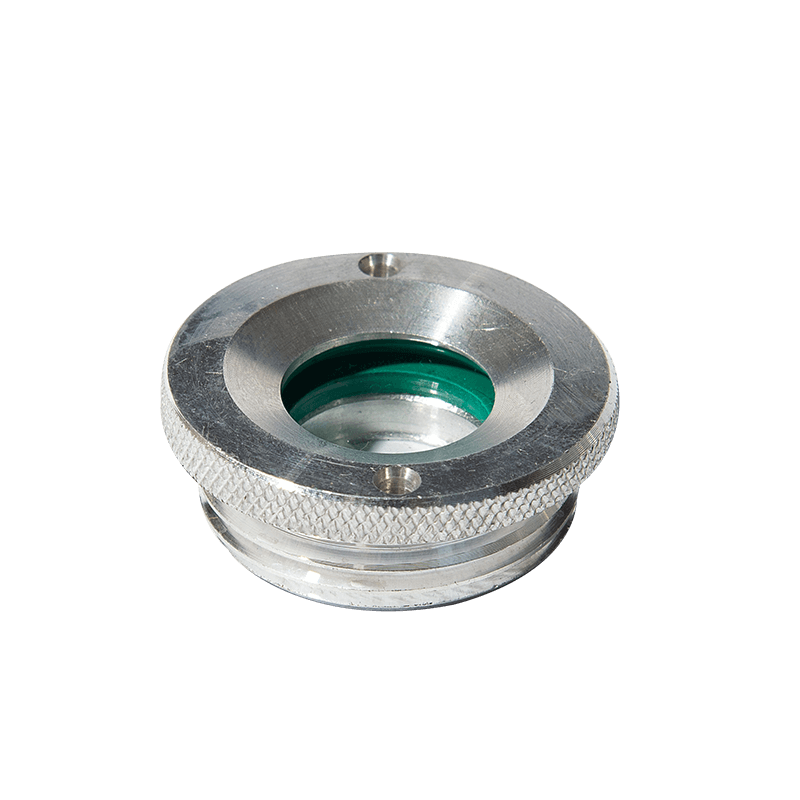

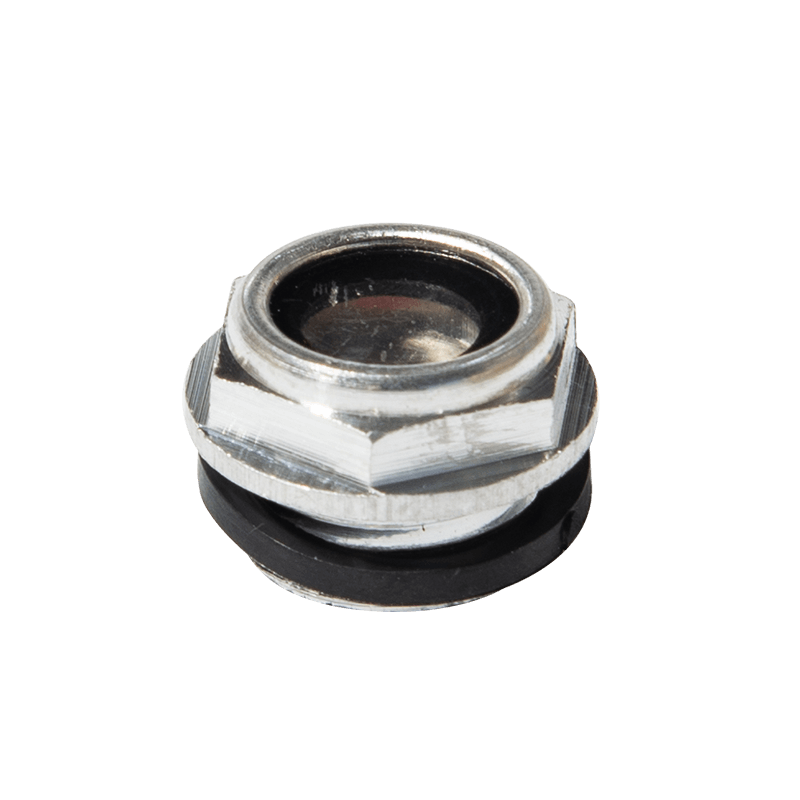

- Venting and Balancing Air Pressure: The breather valve's function is to vent air. It is a specialized component used to replace high-level blockages within the housing. It discharges air generated within the housing during operation, effectively balancing the air pressure inside and outside the reducer.

- Protecting the Oil Seal: By continuously relieving internal pressure, the breather valve prevents excessive stress on the oil seal due to strong internal pressure, thereby protecting it from damage or failure.

- Ensuring Machine Life: By maintaining pressure balance, preventing oil leaks, and ensuring an adequate lubricant supply, the breathing valve ensures effective lubrication of internal gears and bearings, preventing dry grinding and excessive temperature rise, and ultimately significantly extending the service life of the reducer and the entire hydraulic machine.

The breathing valve is a key ventilation valve component that ensures that hydraulic machinery and reducers and other equipment maintain sealing integrity in high temperature or long-term operation environments, prevents lubricating oil leakage, and ensures that internal components are fully lubricated.

Contact Us