Content

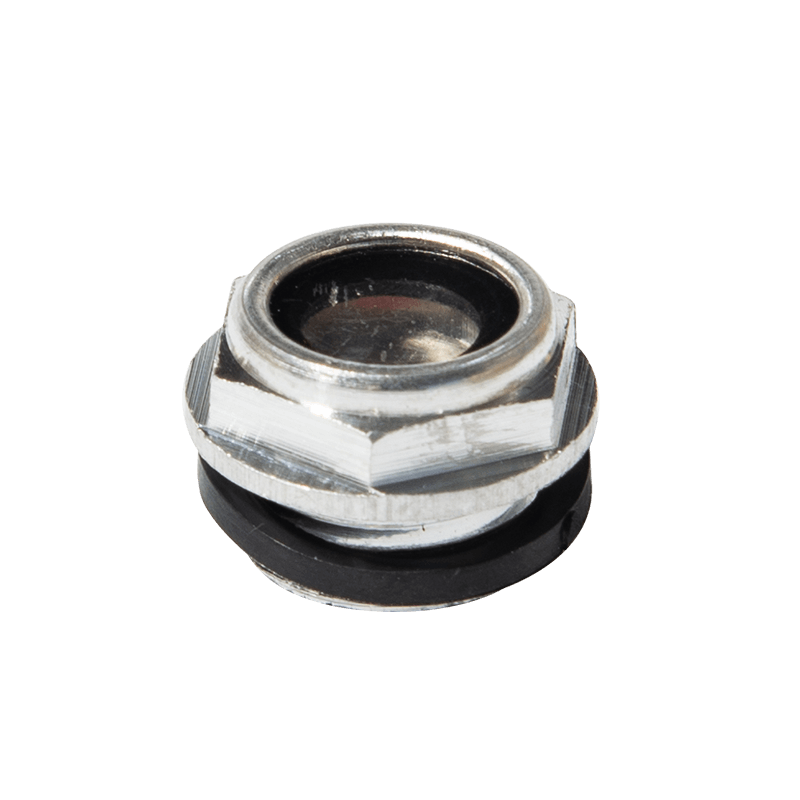

Understanding the "Lifeline" on the Oil Sight Glass

To correctly observe the oil level, you must understand the scale lines on the oil sight glass. A standard oil sight glass usually has upper and lower limits:

- Upper Limit: The maximum oil level allowed in the equipment.

- Lower Limit: The minimum oil level required for normal operation.

The normal oil level range lies between these two limits. This "safety zone" is carefully calculated by the manufacturer; too high or too low oil levels may damage the equipment.

Three Steps to Correctly Observing the Oil Level

1. Ensure the equipment is stationary

Always shut down the equipment and wait a few minutes for the internal lubricant to drain back into the sump. This prevents inaccurate readings caused by flowing, splashing, or foaming oil.

2. Maintain a level eye to eliminate parallax errors

Keep your line of sight level with the center of the oil sight glass when observing. Viewing from the side can cause parallax errors, making you misjudge the oil level.

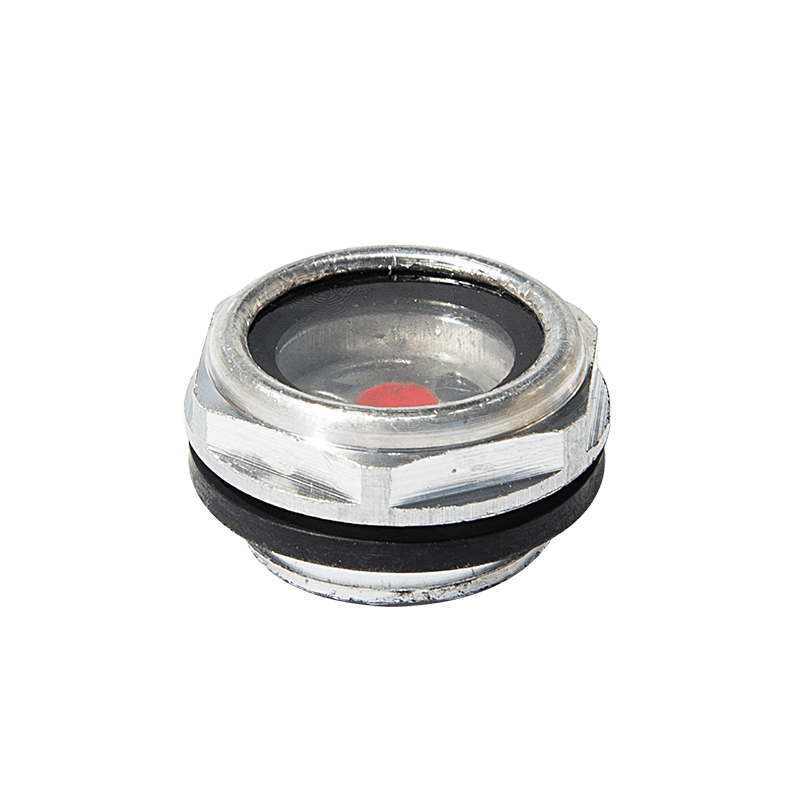

3. Carefully Determine the Oil Level

The oil level typically appears as a clear surface. Compare it with the upper and lower limits:

Oil Level Judgment Results and Actions

- Oil Level Between Upper and Lower Limits: Ideal state. Equipment operates normally; no action required. Record the level for future reference.

- Oil Level Below the Lower Limit: Dangerous. Insufficient lubrication may cause wear or mechanical failure. Replenish oil immediately.

- Oil Level Above the Upper Limit: Potential problem. Excess oil can cause overheating, pressure issues, and leaks. Adjust to drain excess oil.

Proper observation and assessment of the oil level is a simple yet essential check. Regular inspection and timely adjustment can prevent failures, extend equipment life, reduce maintenance costs, and ensure safe, continuous production.

Contact Us