How can the Breathing Filter Valve ensure the accuracy and reliability of its operation under the changing pipeline working conditions?

The design of the float in the Breathing Filter Valve is crucial. It is necessary to ensure that the float is large enough so that the buoyancy it generates is greater than the weight of the moving part, so that when the pressure and liquid level in the pipeline change, the float can float up and down accurately and flexibly to open and close the valve. For example, when the pressure in the pipeline decreases to form a negative pressure, the float can fall in time to replenish air under the action of the difference between the atmospheric pressure and the pressure in the pipe; when the pressure in the pipeline increases, the float can block the exhaust hole under the action of pressure to prevent water from being discharged out of the valve.

The exhaust hole design of the Breathing Filter Valve needs to consider the exhaust requirements under different gas volume conditions. For the case of less gas volume, set a small hole to let the float fall for exhaust; for the case of more gas volume, set a large hole to let the float fall for exhaust. At the same time, during the air replenishment process, due to the different pressure effects of the large and small exhaust holes, the float with the large hole is lifted up and closed first, and then the small hole is closed. This can delay the full closing process, ease the pressure rise of the water column when closing, and ensure the stability and reliability of the valve.

Buffer devices, such as adjustable buffer devices and reverse indication buffer devices, are set on the upper part of the Breathing Filter Valve to prevent the sealing surface from being hit too much, protect the sealing performance of the valve, extend the service life of the valve, and ensure the accuracy and reliability of the valve during long-term use.

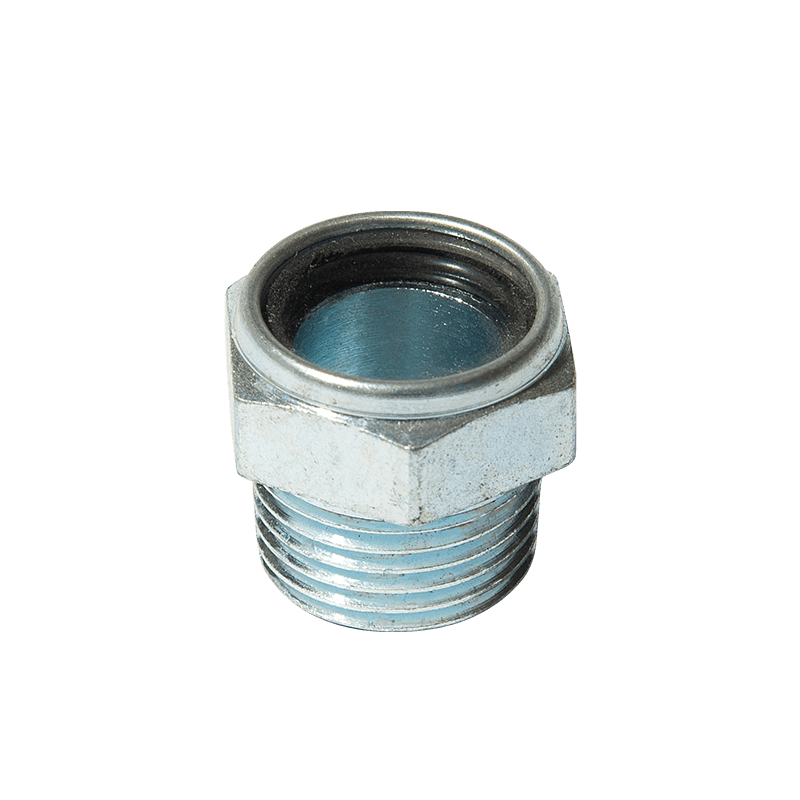

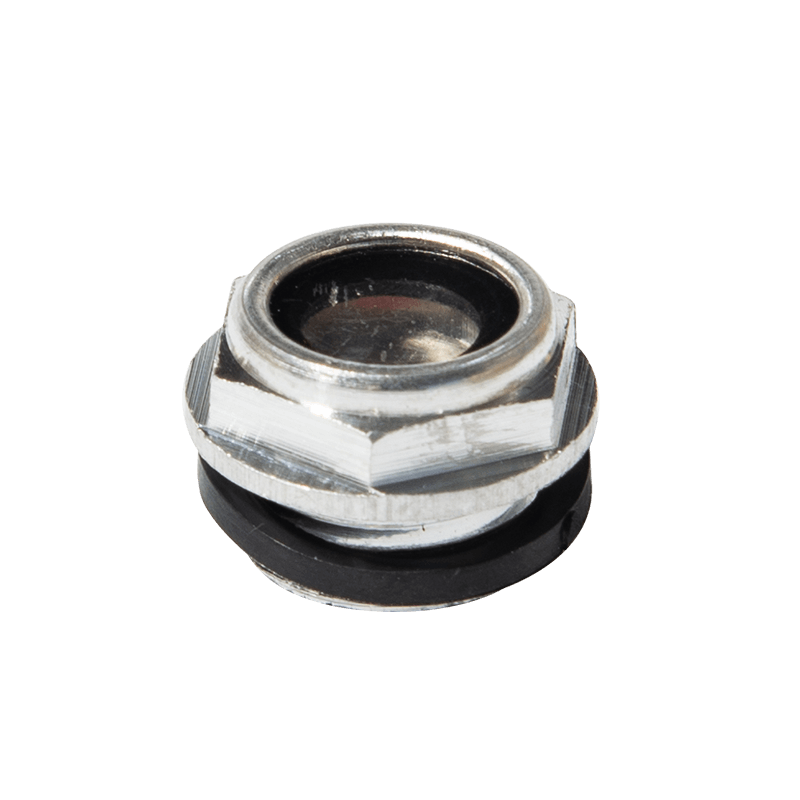

The valve stem should be made of stainless steel to prevent rust and jamming, which will affect the flexibility of the movement; the float material should be selected from reliable quality and stable buoyancy to ensure that it can work normally under different working conditions. The sealing surface should be carefully ground, and high-hardness and wear-resistant materials should be used. There should be no water leakage after closing. For example, materials such as polytetrafluoroethylene or graphite mixed with glass fiber can be used to make the valve seat, high-hardness sealing gaskets can be used, and labyrinth sealing surfaces can be used to improve the sealing performance and prevent valve leakage.

Check the air valve regularly, including appearance inspection and internal parts inspection. Check whether the valve body, valve cover, etc. are damaged or corroded, and whether the valve disc, valve seat, guide rod, guide hole, spring, etc. are rusty and fouled. For example, conduct a comprehensive inspection of the air valve every month or quarter to promptly discover and deal with potential problems.

Open the top cover of the air valve, clean the internal valve disc, valve seat, guide rod, guide hole, spring and other parts, and clean them with kerosene if necessary. At the same time, check whether the valve disc is flexible and whether it is stuck, and lubricate the moving parts to ensure smooth movement of the valve. For example, regularly refuel the valve stem to reduce friction and improve the reliability of the valve. If the valve disc, valve seat, spring and other parts are found to be damaged or severely worn, they should be replaced in time to ensure the sealing performance and movement accuracy of the valve. For example, when the sealing surface is scratched or worn, the seal should be ground or replaced in time.

Contact Us