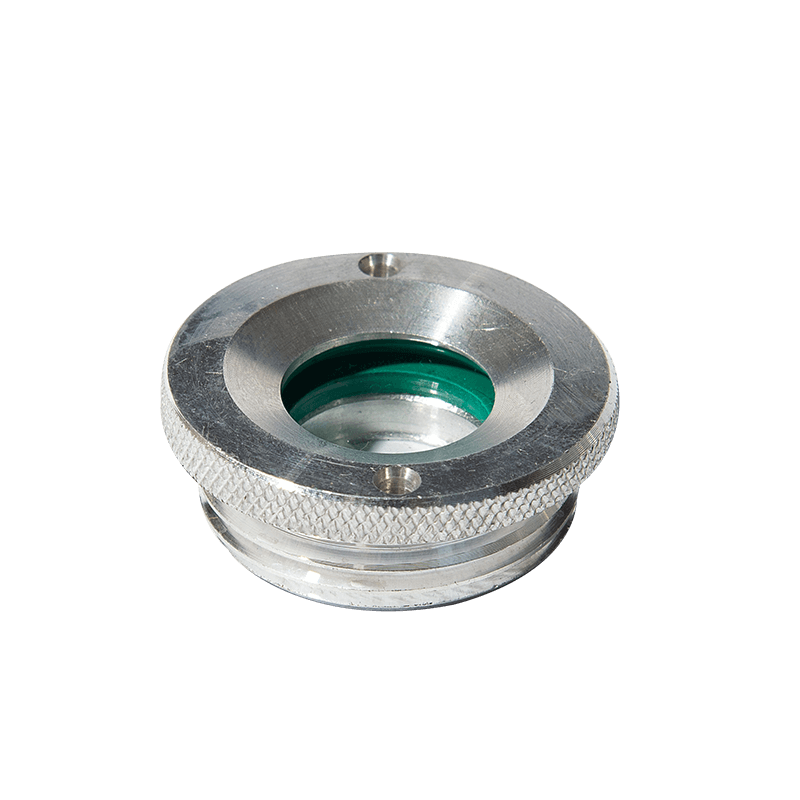

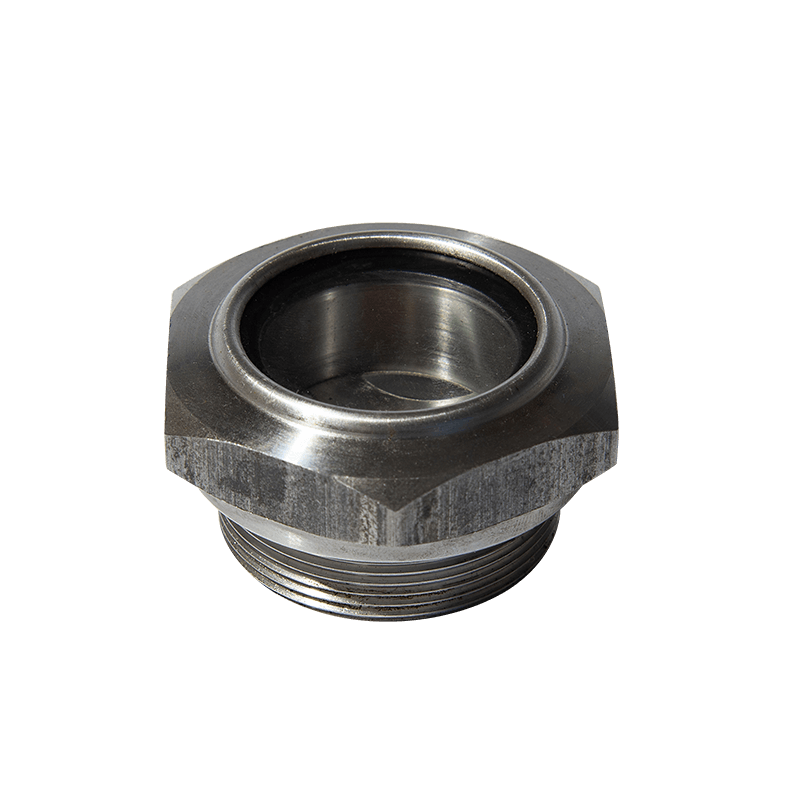

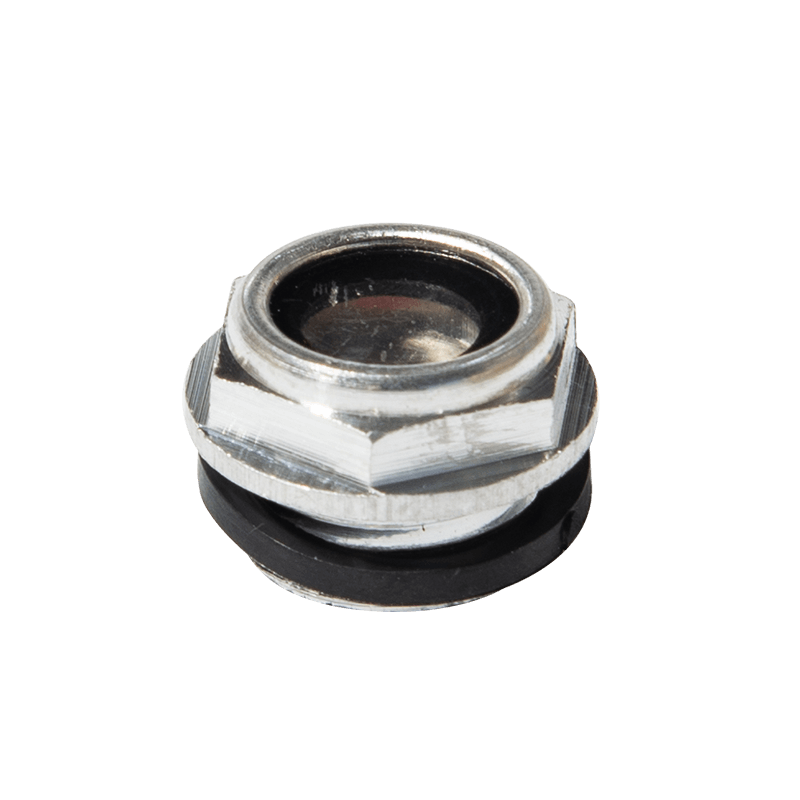

What is the main function of the aluminum oil plug in the reducer?

The main function of the aluminum oil plug in the reducer is to balance the atmospheric pressure inside and outside the reducer and ensure the normal discharge of the gas inside the box when the reducer is running. In addition, the aluminum oil plug also has the following functions:

Lubrication: By introducing lubricating oil into the reducer, the friction between moving parts such as gears and bearings is reduced, and wear is reduced, thereby extending the service life of the reducer.

Heat dissipation: The lubricating oil can transfer the heat generated inside the reducer during operation, play a heat dissipation role, and prevent the high temperature from affecting the performance of the equipment.

Sealing: The oil plug can prevent external impurities (such as dust, moisture, etc.) from entering the reducer, ensuring the cleanliness of the lubricating oil and the normal operation of the equipment.

Exhaust function: During the operation of the reducer, when the internal gas cannot be discharged smoothly, the oil plug can be used as an exhaust hole to help discharge the gas and prevent the high air pressure from affecting the performance of the equipment.

Oil filling and drainage: The oil plug can also be used as an oil filling port, which is convenient for adding lubricating oil to the reducer when needed; at the same time, it can also be used as a drainage port to discharge old oil and impurities.

Aluminum oil plugs are suitable for various types of reducers, including gear reducers, worm reducers and planetary gear reducers. Its structural design is easy to install and disassemble, and has good sealing and stability.

In practical applications, aluminum oil plugs not only play the role of exhaust, sealing and lubrication, but also play an important role in maintenance and operation. It is one of the key components to ensure efficient and stable operation of reducers.

Contact Us